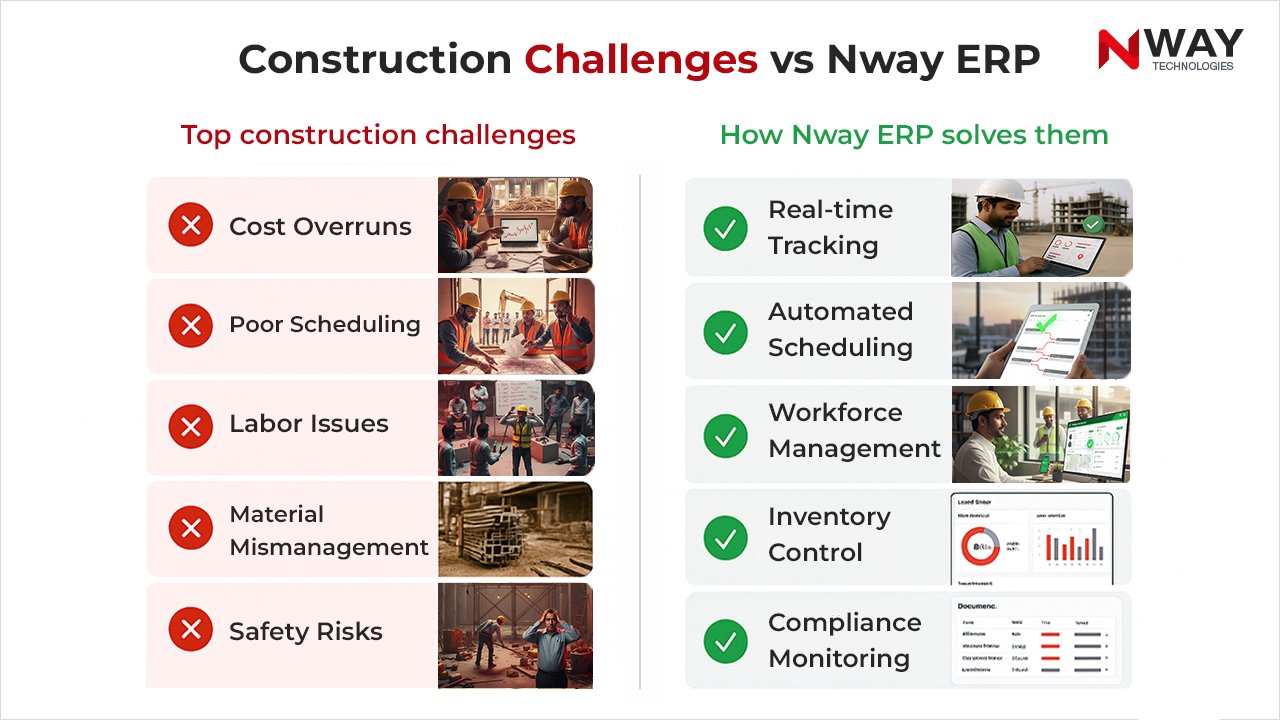

Manual systems and fragmented data no longer cut it in today’s construction world. Many projects face cost overruns, delays, and rework, often accounting for 5–10% of total project costs. AI-enabled ERP software unifies workflows, automates documentation, and provides predictive insights into resources and costs. By leveraging AI-driven construction management and smart ERP solutions for contractors, firms can reduce material wastage, improve planning, and gain real-time visibility across sites – making AI-integrated ERP a decisive advantage in the future of construction technology 2026.

In this blog, we’ll learn about why AI-enabled ERP is the new necessity for construction companies looking to scale their businesses in 2026.

Table of Contents:

Construction Inefficiencies, Rework, Cost Overruns & Delays

High incidence of rework and hidden costs

Industry research shows rework is a common and costly problem. According to a recent summary, rework alone can account for 5-10% of the total project cost.

Some studies put rework-related cost as high as 11% for certain projects.

Rework typically arises from issues such as outdated drawings, poor documentation, manual entry errors, miscommunication between stakeholders, or incomplete tracking of material, labour, or site activity.

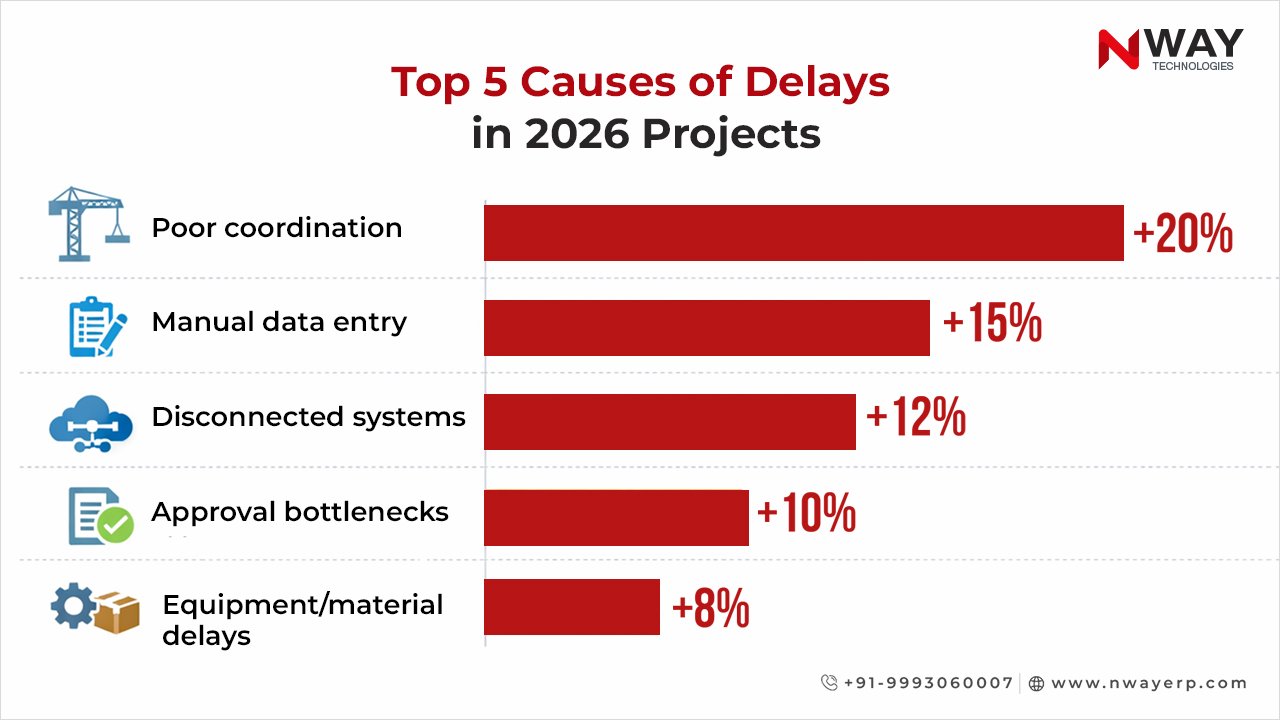

Frequent cost overruns and delayed timelines

For many infrastructure and heavy-civil projects, cost overruns remain common. Meta‑analyses of global transportation and infrastructure builds show that a majority of projects exceed their original budgets.

These overruns stem from scope changes, delays, poor material or labour forecasting, fragmented data flow, and unpredictable site conditions.

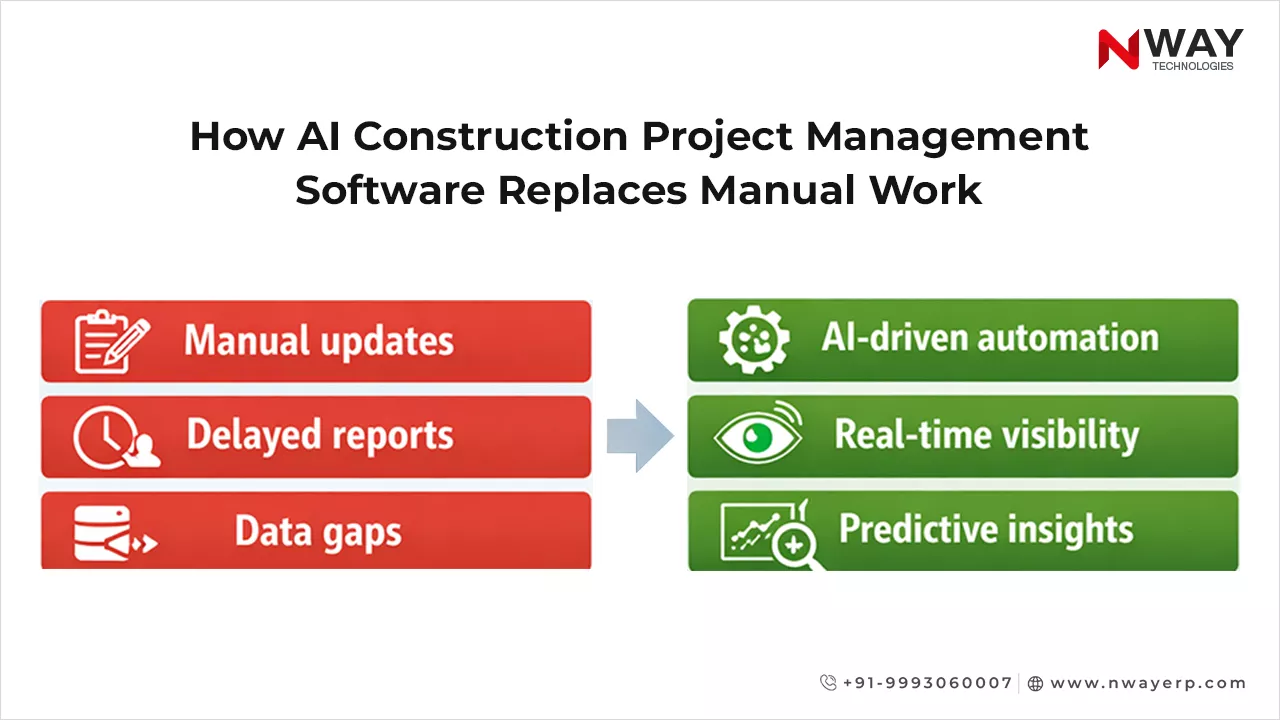

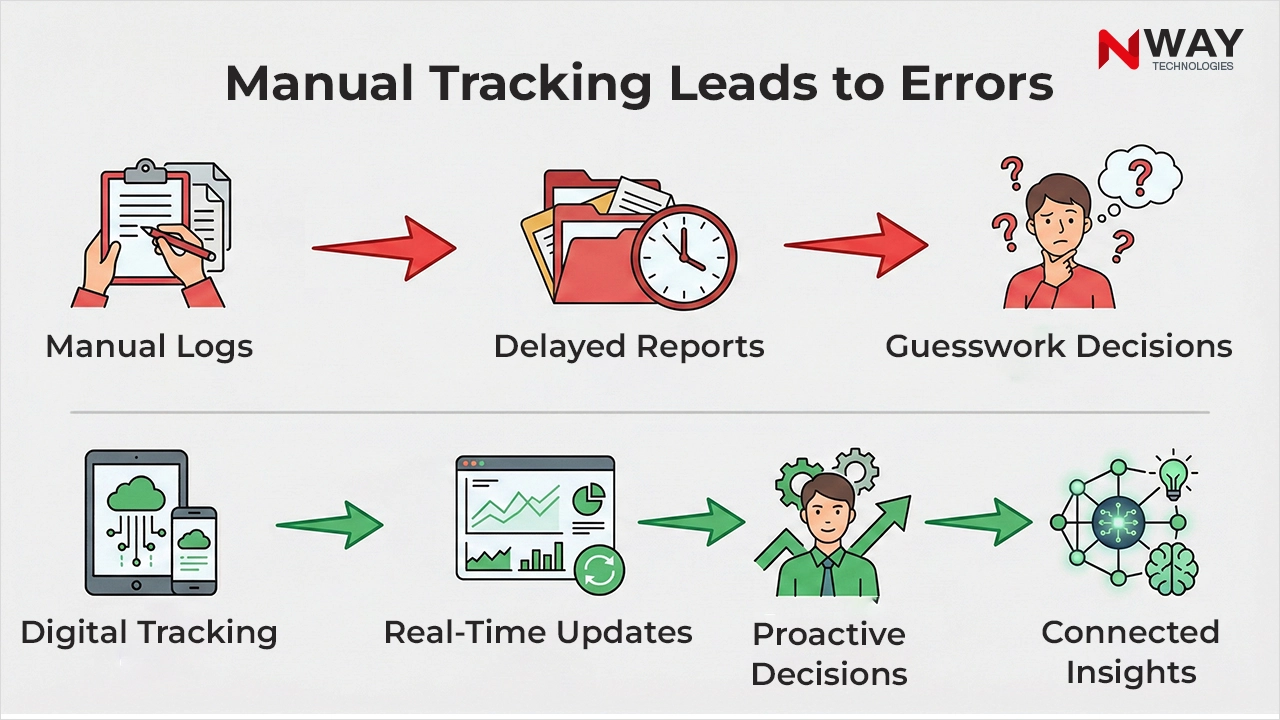

Fragmented data, manual processes and siloed workflows

Most traditional construction management relies on multiple disconnected systems – spreadsheets, paper bills, stand‑alone accounting or procurement tools, separate site logs for labour and materials, and fragmented approval chains. This fragmentation leads to delays, data loss or errors, duplicate work, and lack of oversight.

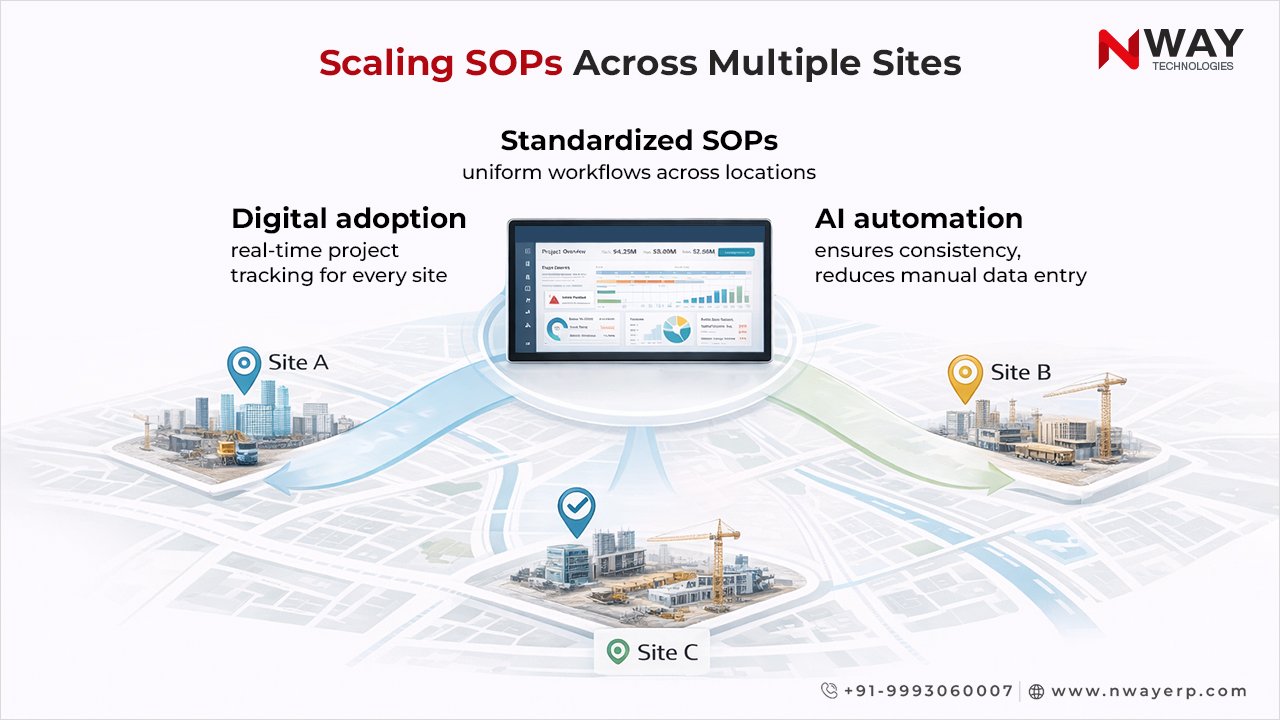

When a project spans multiple sites (roads, bridges, infrastructure, ready-mix concrete, mining, etc.), these inefficiencies multiply – leading to material waste, duplicated efforts, delayed payments, poor cash flow, and lower profitability.

In 2026, given tighter margins, regulatory compliance, labour‑cost pressures, and rising material costs, these inefficiencies are no longer acceptable. Construction firms need systems that enforce clarity, accuracy, and real‑time visibility across all operations.

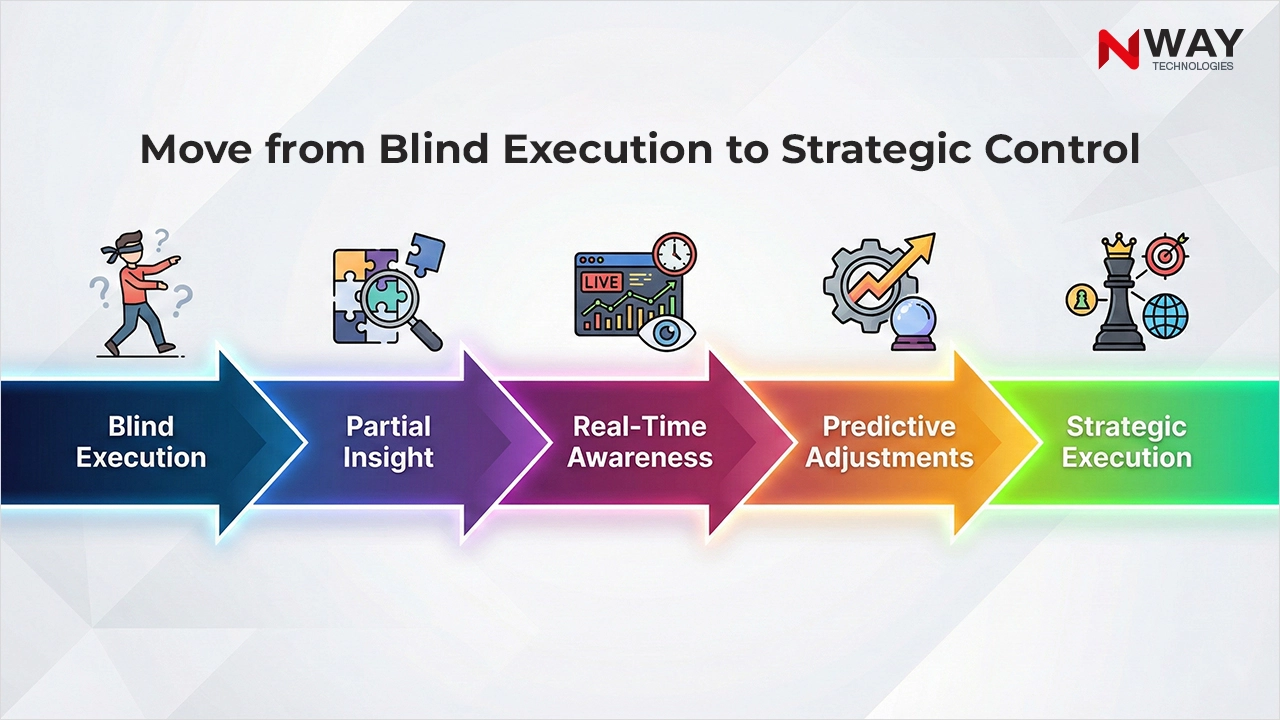

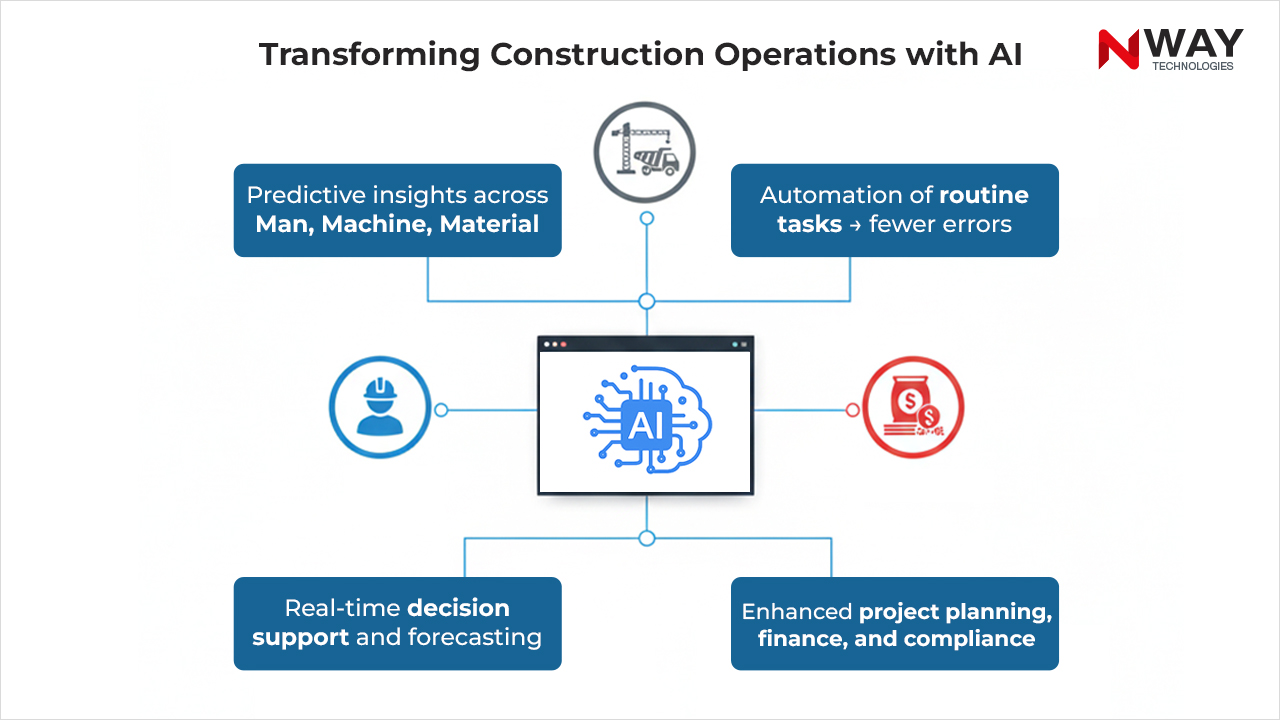

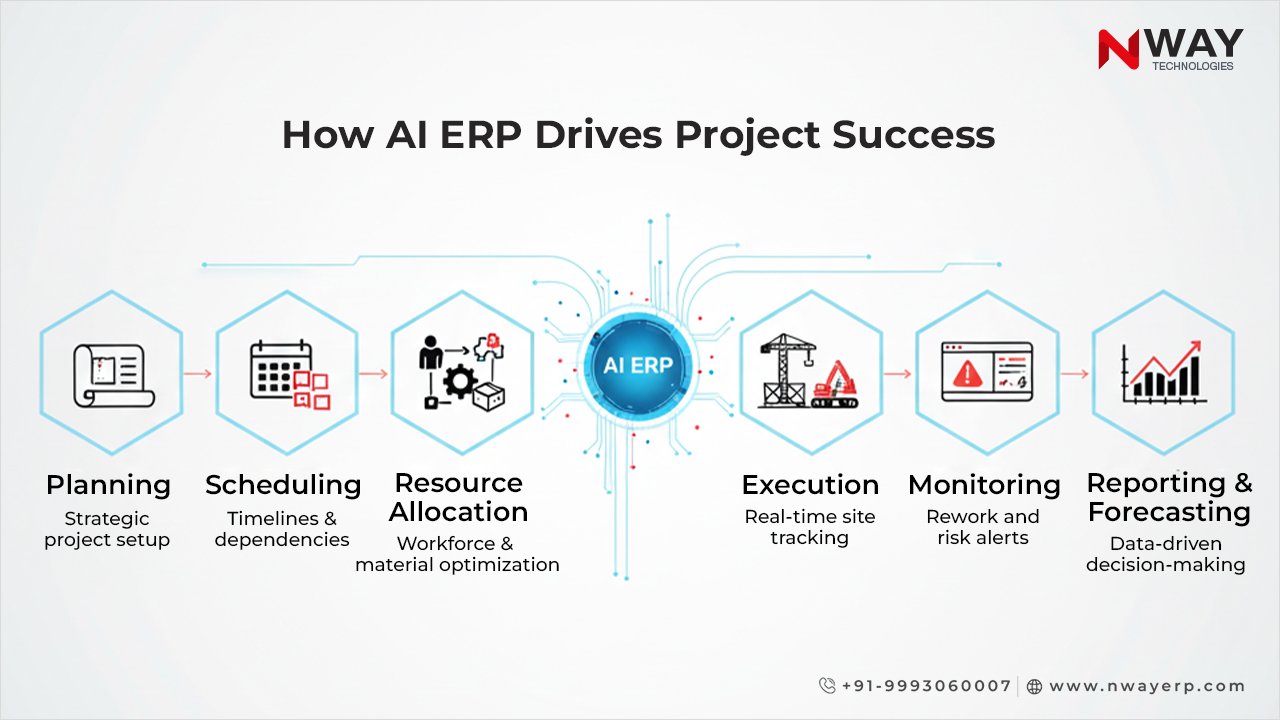

How AI-Enabled ERP Software Can Solve These Challenges

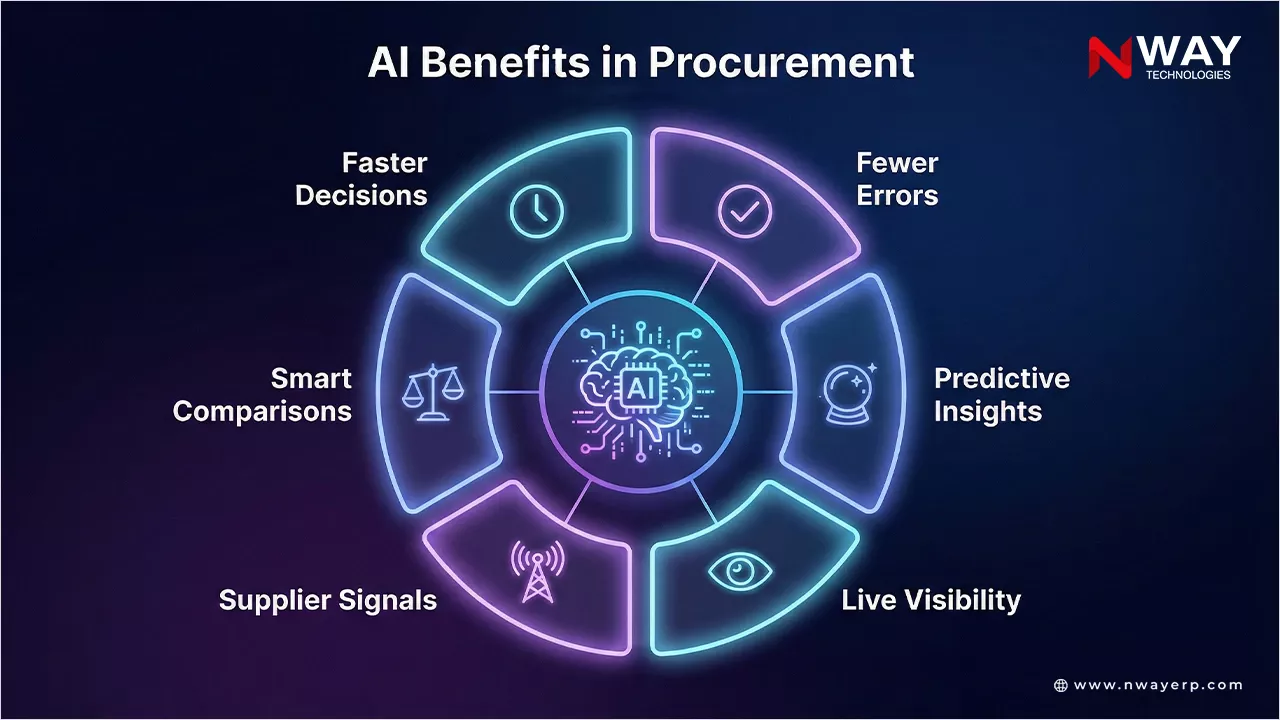

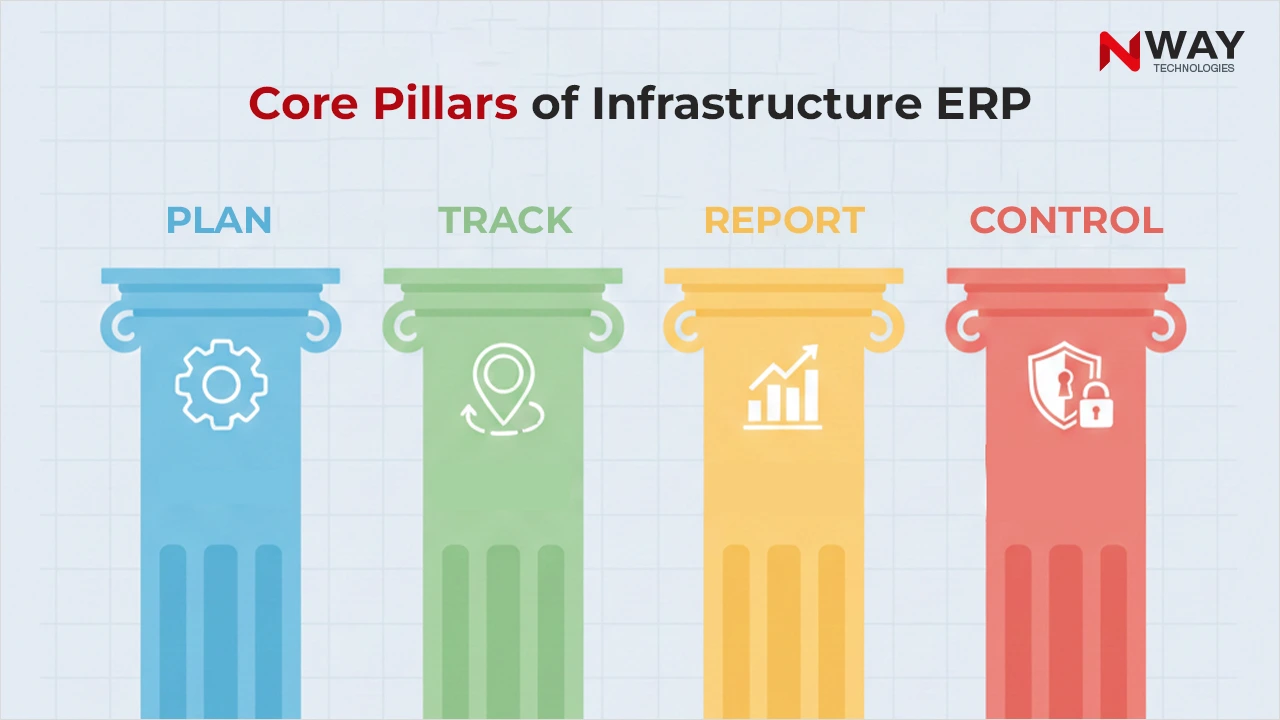

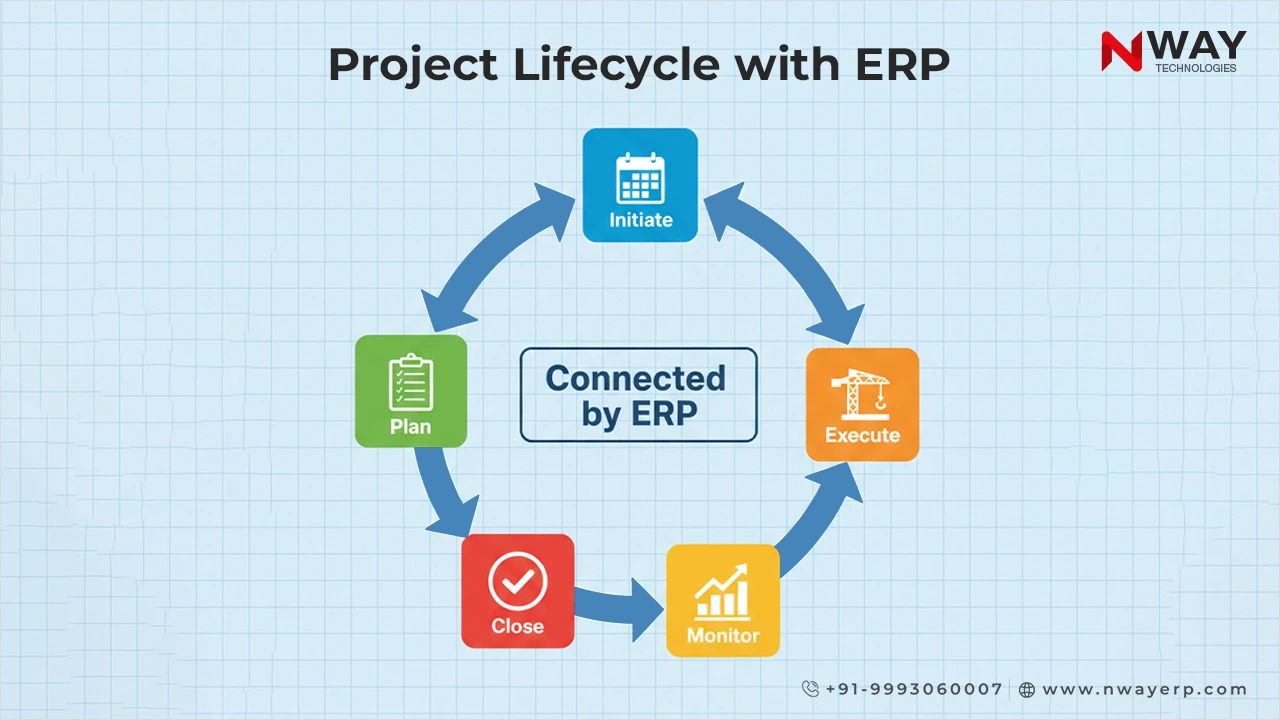

AI enabled ERP software combines traditional ERP capabilities with automation, intelligent data processing, and real-time integration across modules. Here is how it addresses the core problems:

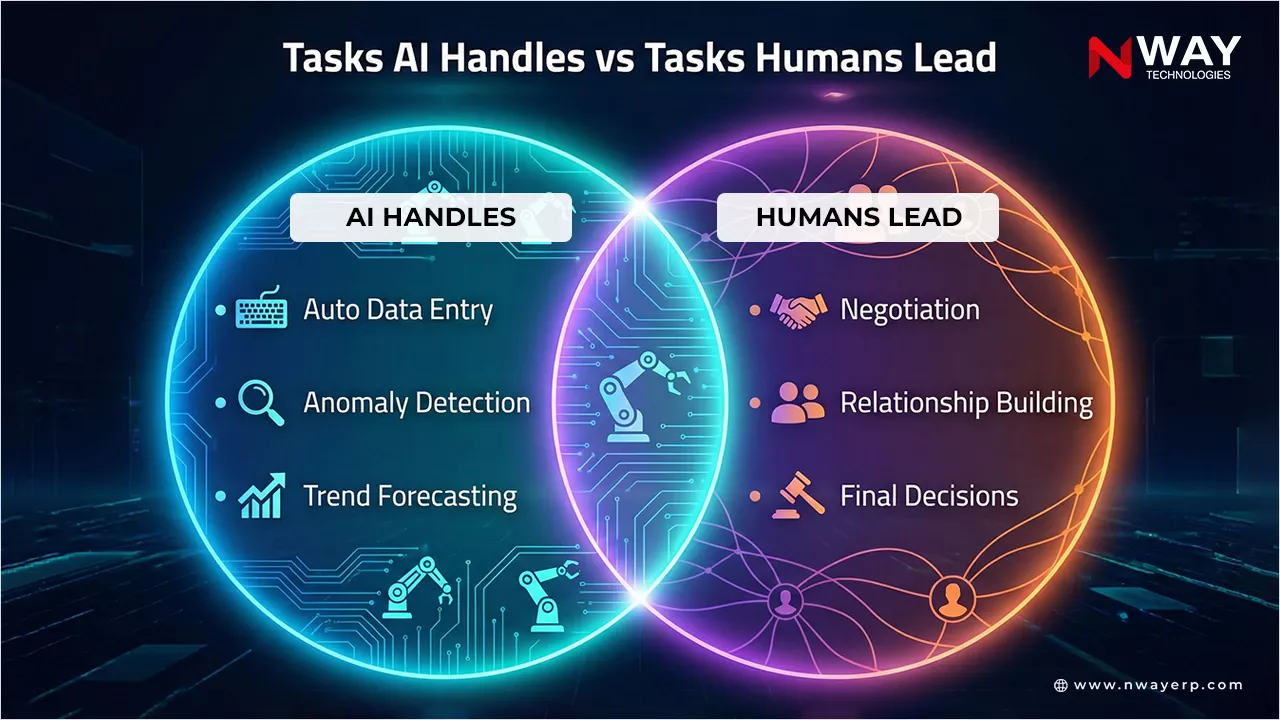

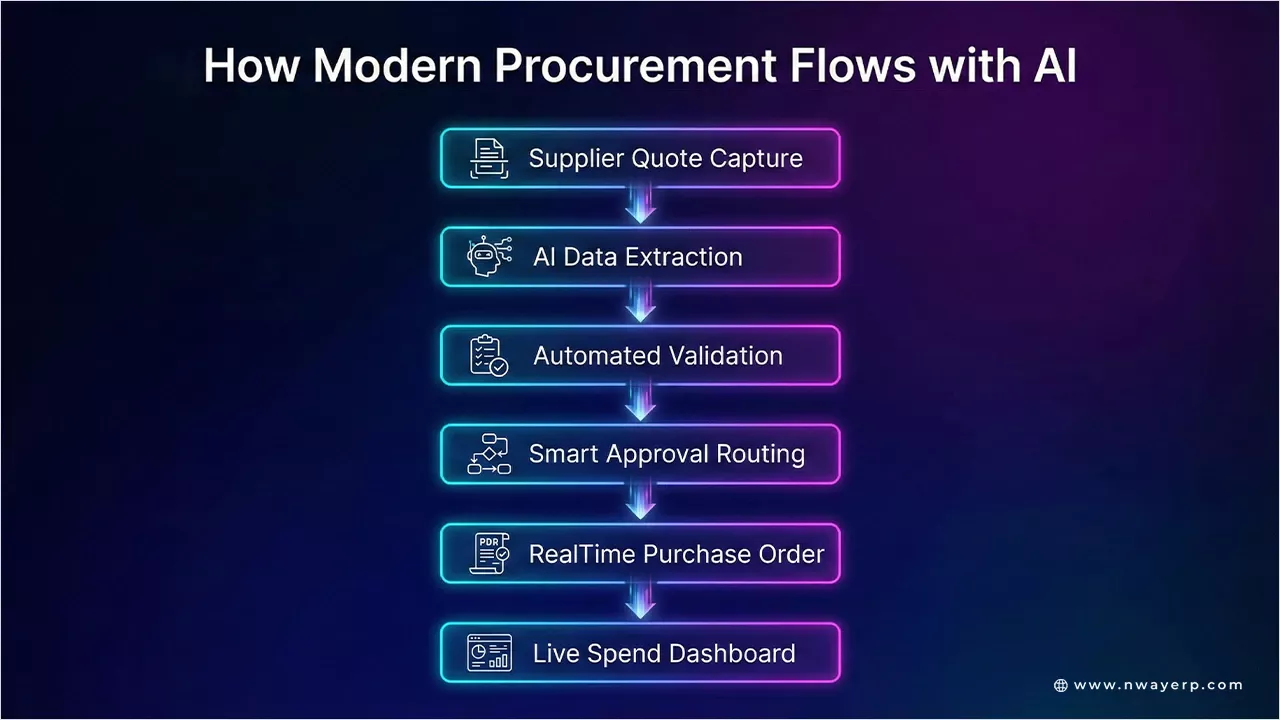

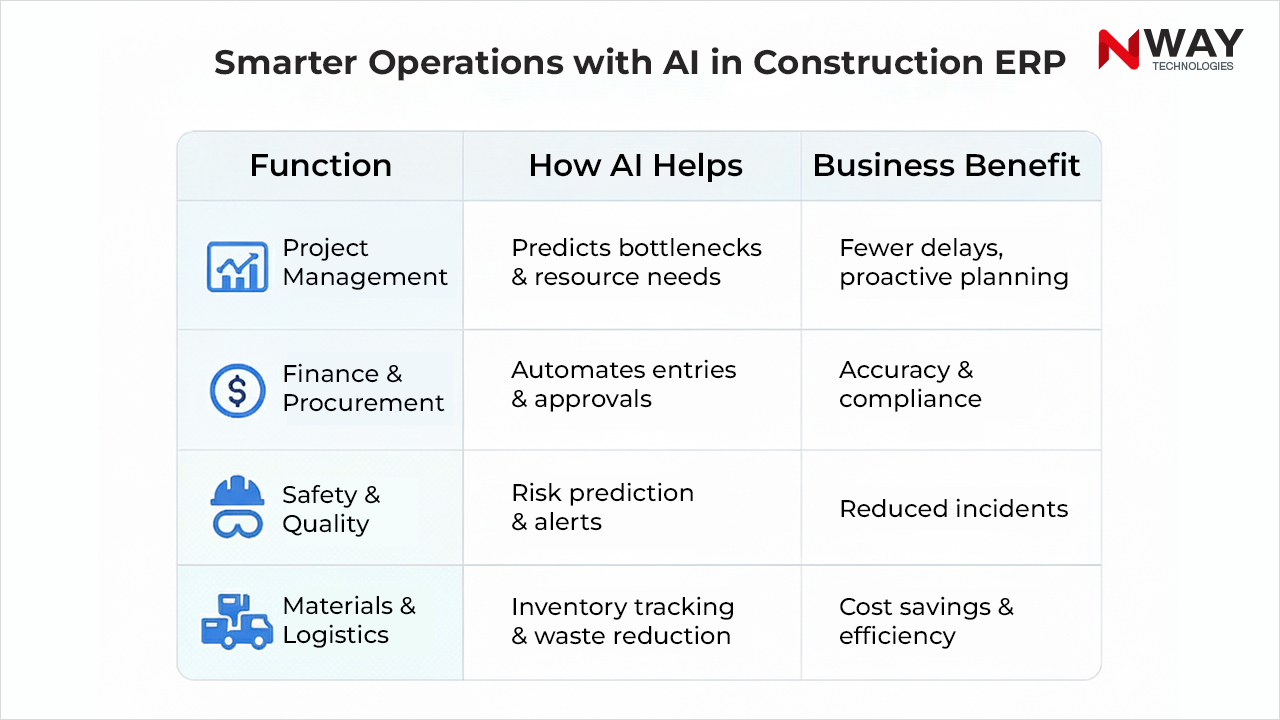

Accurate and automated documentation

Instead of manual invoice entry, manual GRNs, or paper-based receipts, AI‑powered systems automate data capture and document processing. This reduces human error, ensures accurate records, and avoids data loss or duplication. This directly addresses causes of rework and documentation-related cost leakages.

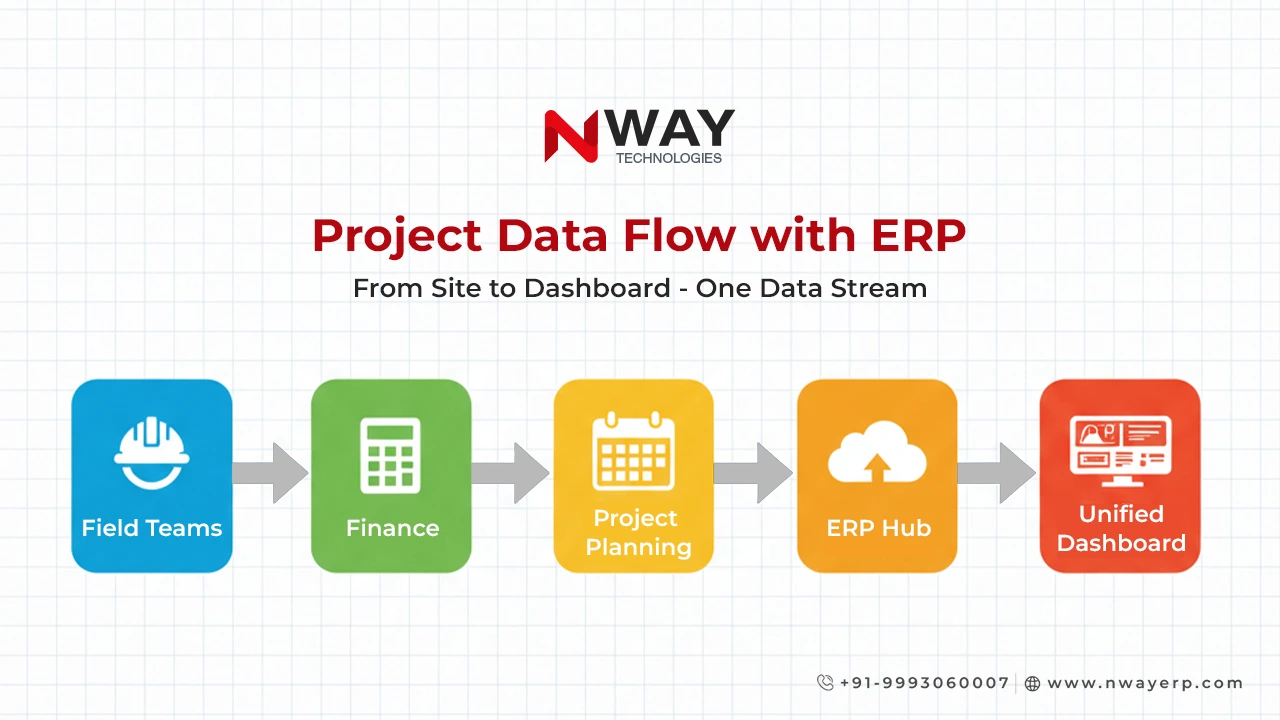

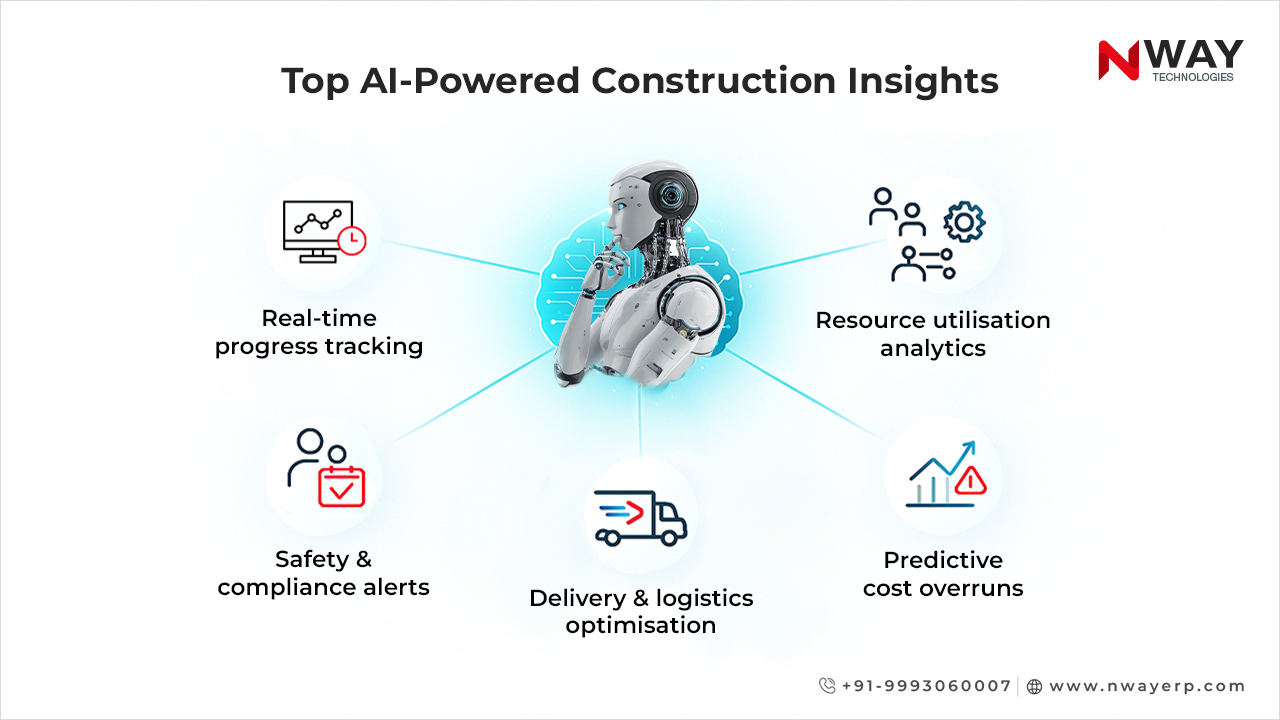

Real-time, unified data across all departments and sites

With integrated modules – procurement, inventory, finance, labour, equipment – and a central data repository, managers get a consistent, real‑time view of project status. This avoids miscommunication and ensures every stakeholder works from the same updated data.

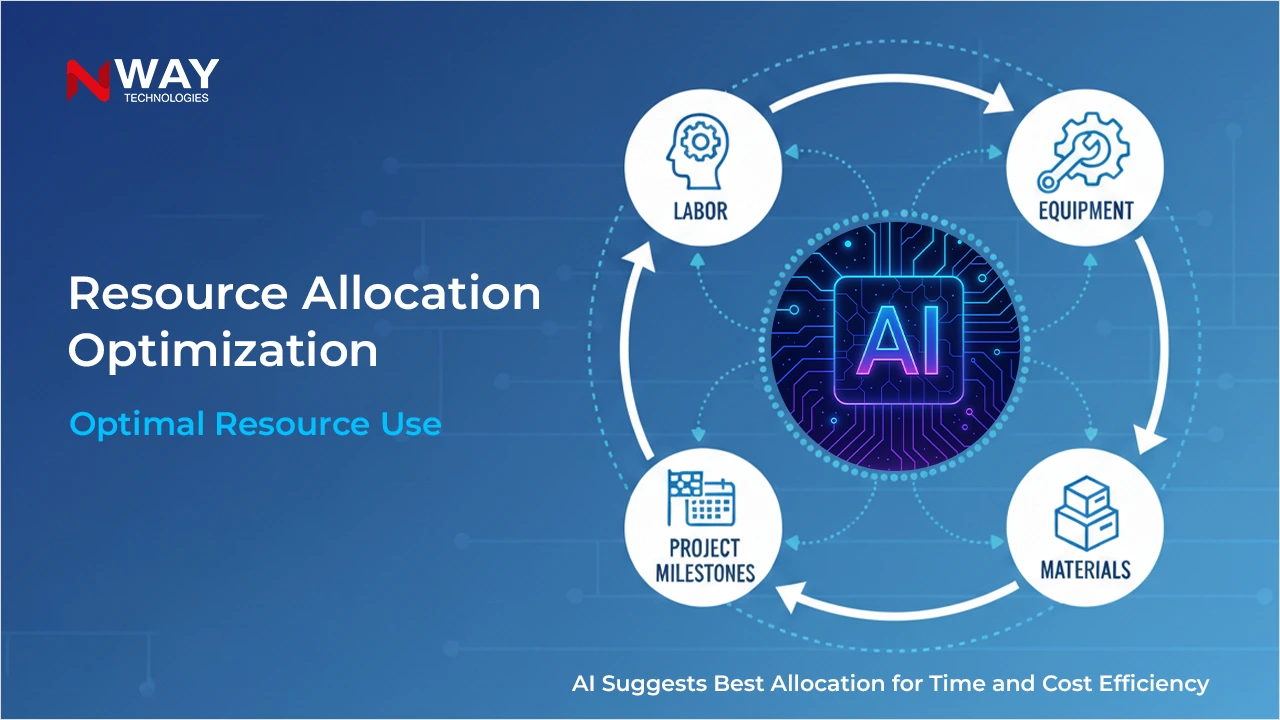

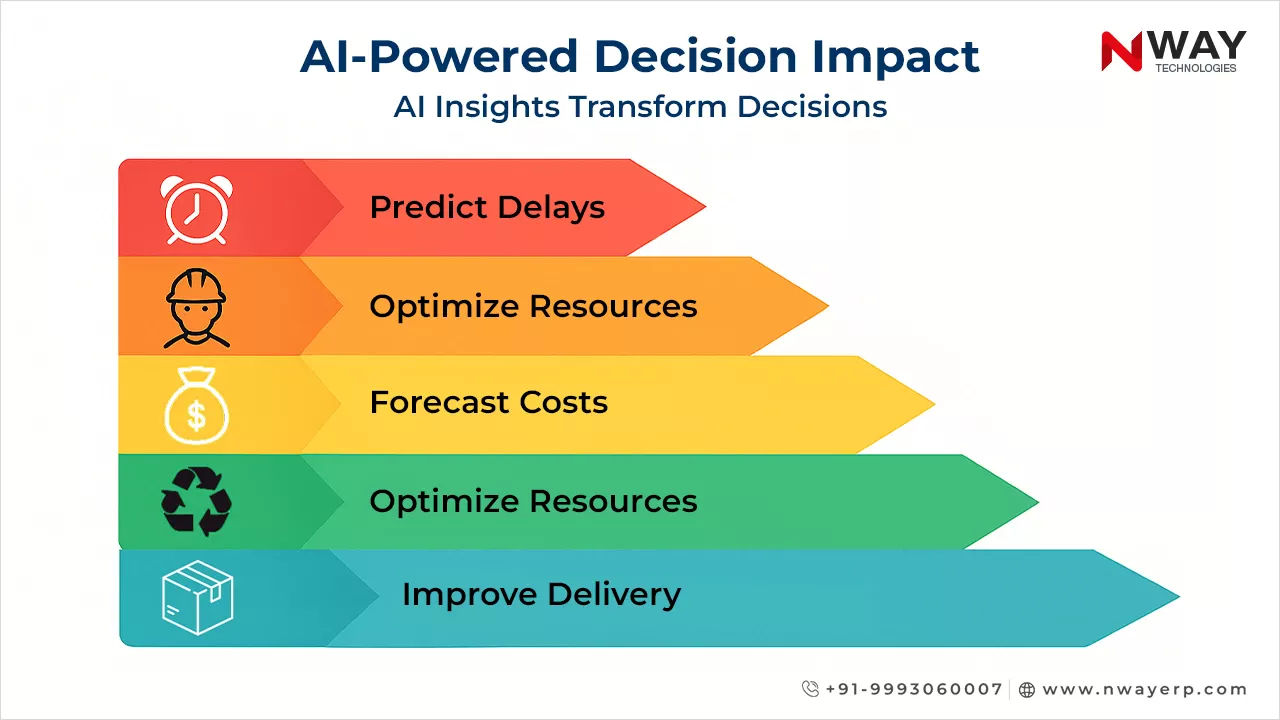

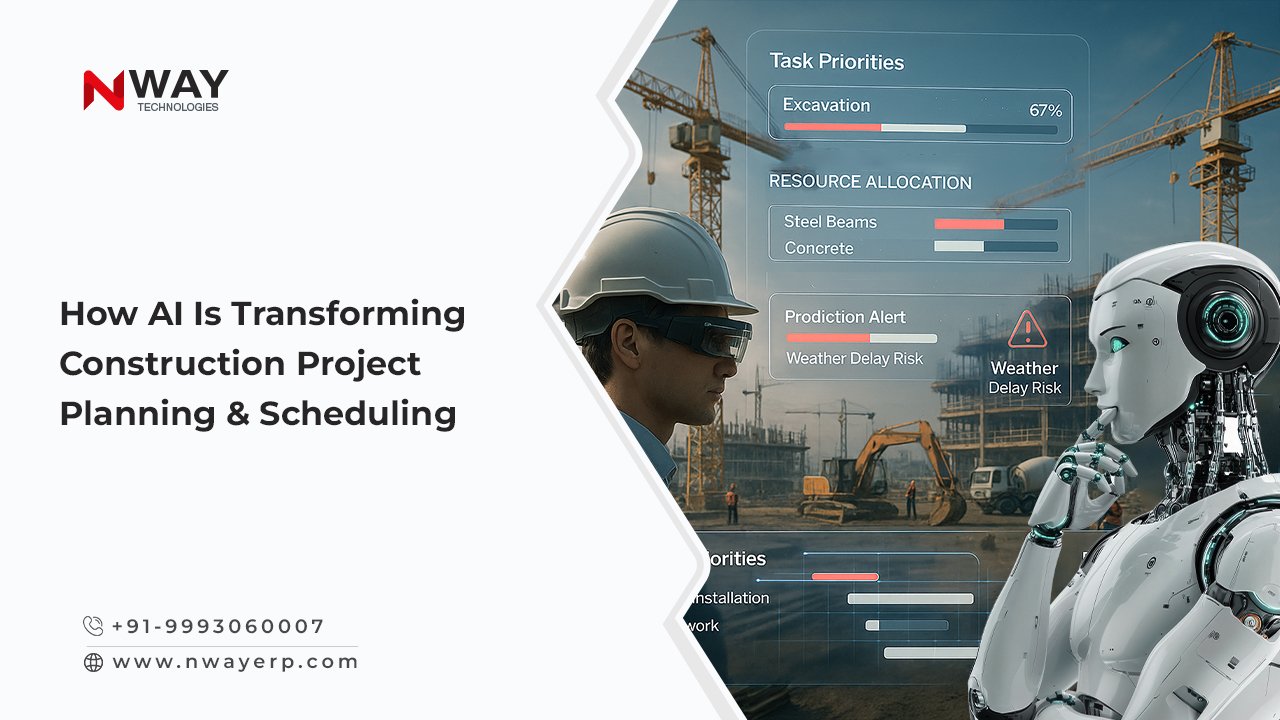

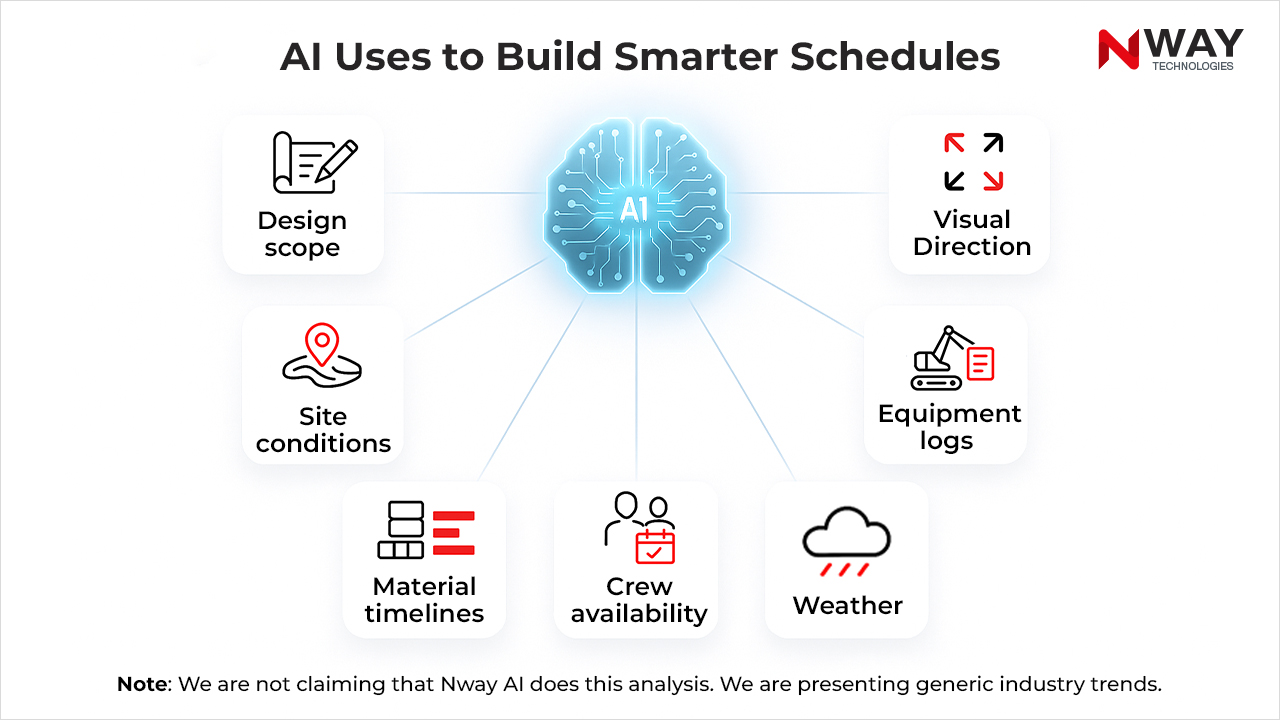

Predictive forecasting for materials, labour, costs, and cash flow

AI analytics can predict materials demand, labour needs, equipment maintenance cycles, cash flow requirements, and potential cost overruns. Early visibility enables proactive decisions: ordering only what is needed, scheduling work to avoid delays, and avoiding budget surprises.

Predictive forecasting for materials, labour, costs, and cash flow

AI analytics can predict materials demand, labour needs, equipment maintenance cycles, cash flow requirements, and potential cost overruns. Early visibility enables proactive decisions: ordering only what is needed, scheduling work to avoid delays, and avoiding budget surprises.

Faster approvals and streamlined workflows

Digital workflows mean approvals – for vendor payments, material requisitions, site bills – happen faster. This reduces bottlenecks, accelerates cash flow, and avoids idle labour or material waiting time.

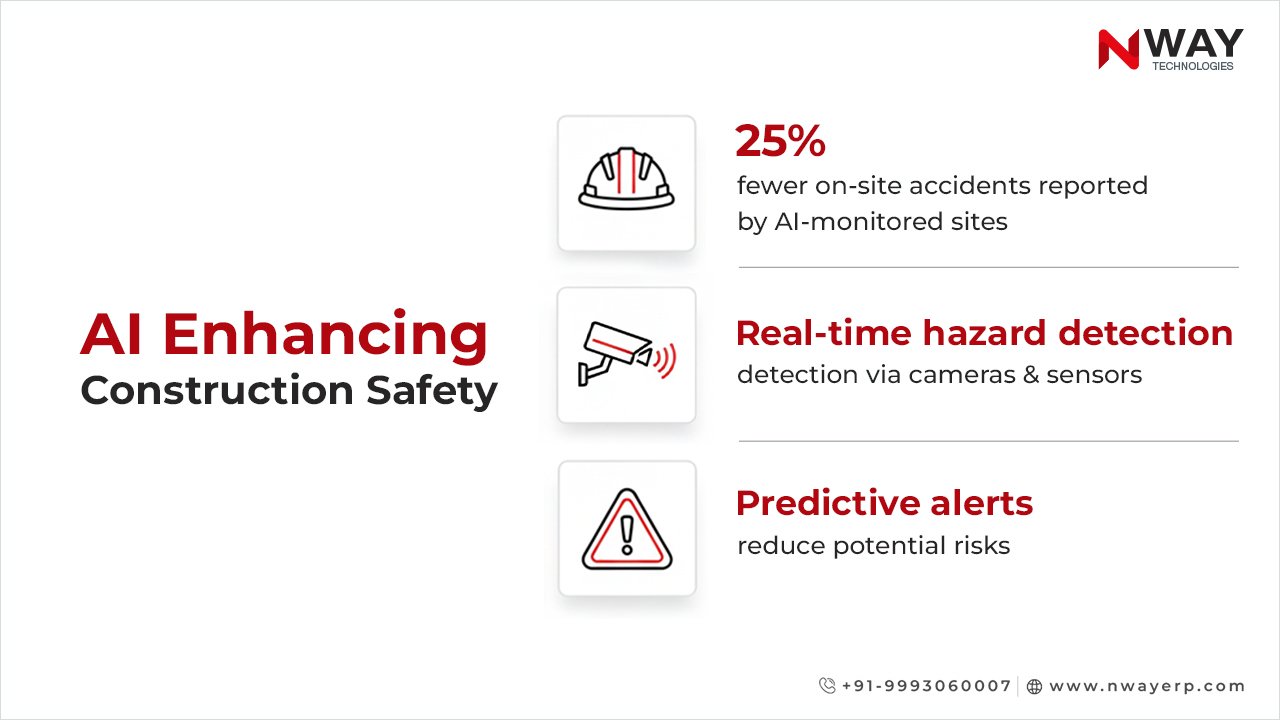

Risk mitigation and better resource utilization

With better documentation, forecasting, and data integrity, firms can reduce waste, avoid duplicate work, and prevent frequent rework – lowering both direct and indirect project costs. Real-time visibility also helps detect deviations early and take corrective action on time.

Together, these capabilities transform ERP from a passive back-office tool into an active operations control system.

Traditional ERP vs Generic Construction ERP vs AI-Driven Construction ERP

| Outcome / Capability |

Traditional ERP |

Generic Construction-oriented ERP |

AI-Driven Construction ERP |

| Data Entry & Documentation |

Manual, error-prone |

Semi-automated |

Automated & accurate records |

| Real-Time Site & Project Visibility |

Very limited |

Partial, delayed |

Full, live data dashboards |

| Material / Labour / Cash Forecasting |

Estimate-based |

Moderate forecasting |

Predictive, data-driven forecasts |

| Multi-Site / Multi-Module Coordination |

Difficult, often siloed |

Some integration, manual effort |

Seamless integration across all sites & modules |

| Rework & Waste Risk |

High |

Moderate |

Significantly reduced |

| Approval, Billing & Workflow Speed |

Slow, manual |

Faster than paper, but some delay |

Rapid, streamlined, automated |

| Decision Support for Management |

Weak, reactive |

Better but limited |

Strong, proactive, data-based |

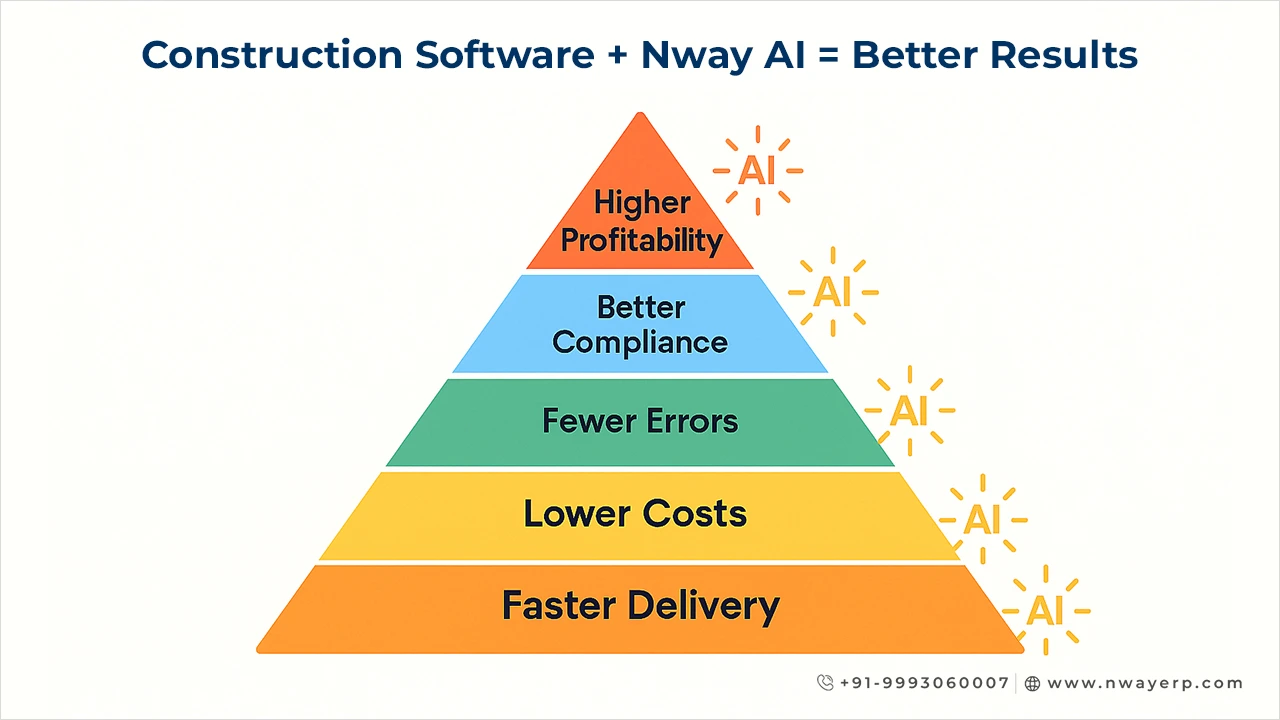

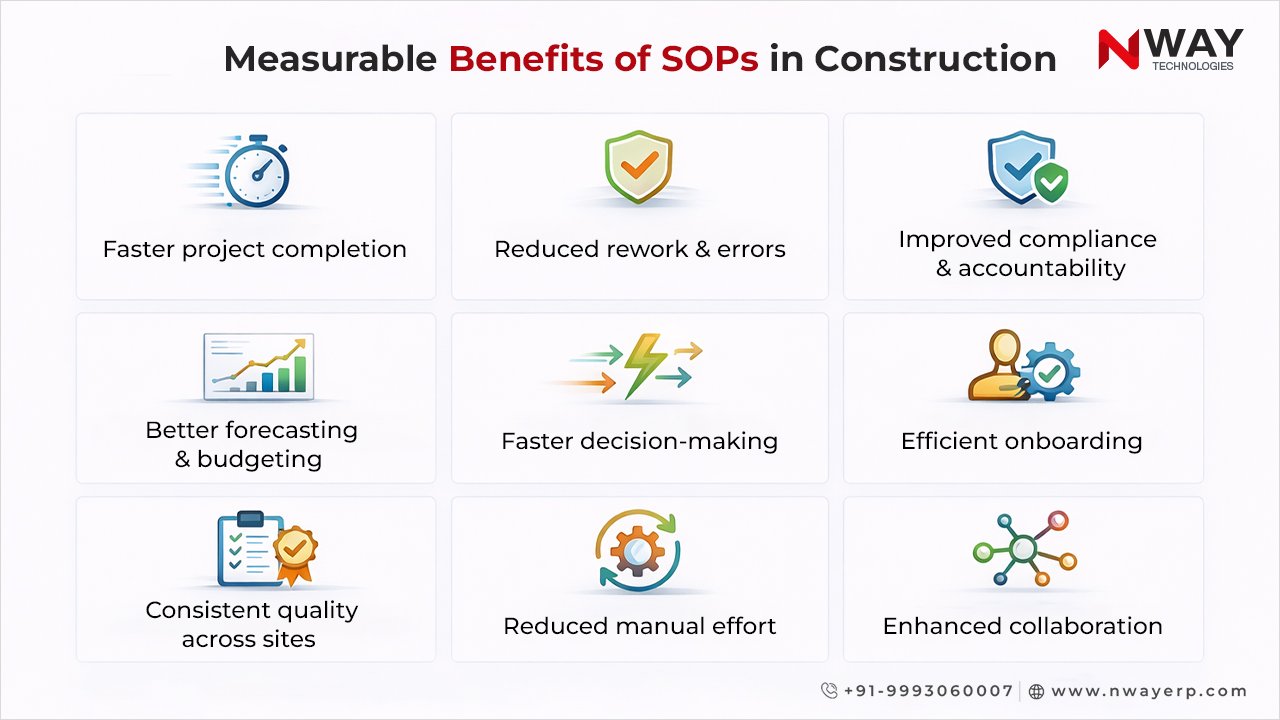

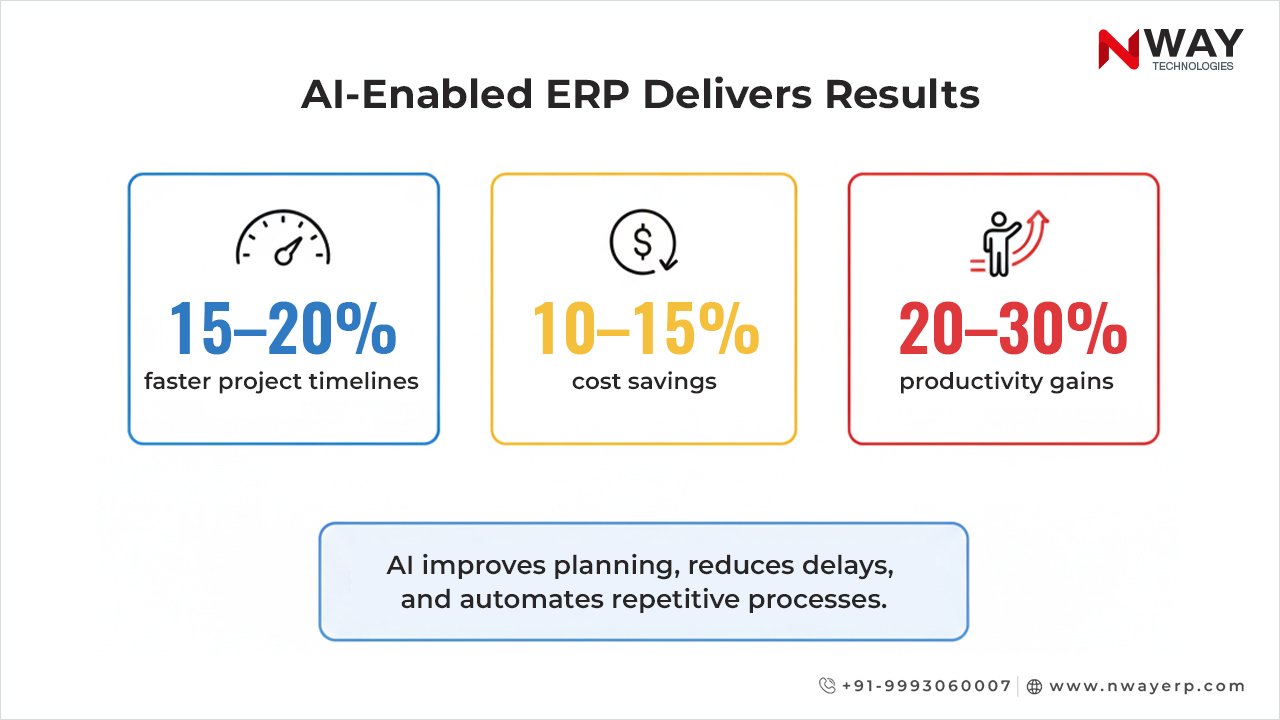

Outcome for Construction Firms: With AI‑driven construction ERP, firms can expect fewer delays, lower waste, improved cost control, better cash flow, more predictable project delivery, and higher profitability.

Why Firms Operating Infrastructure, Road & Bridge, or Multi‑Site Projects Need AI-Enabled ERP

Construction firms working on heavy infrastructure – roads, bridges, real estate, mining, ready‑mix concrete plants, multi‑store setups – face complex workflows:

- Large volumes of materials

- Frequent vendor transactions

- Many labourers, shifts, daily attendance and payroll

- Multiple sites generating data simultaneously

- Heavy equipment usage and maintenance requirements

- Cash-flow dependencies and payment cycles across sites

In such contexts, manual processes and fragmented systems are not just inefficient – they are risky. They cause material wastage, labour idle time, delayed payments, rework, miscommunication, and budget blowouts.

AI-driven ERP delivers value by making operations transparent, manageable, and predictable – giving contractors control over cost, schedule, resources, and profitability.

Wondering where your road and bridge projects are losing time or money?

Get a free project health assessment with Nway ERP’s AI insights.

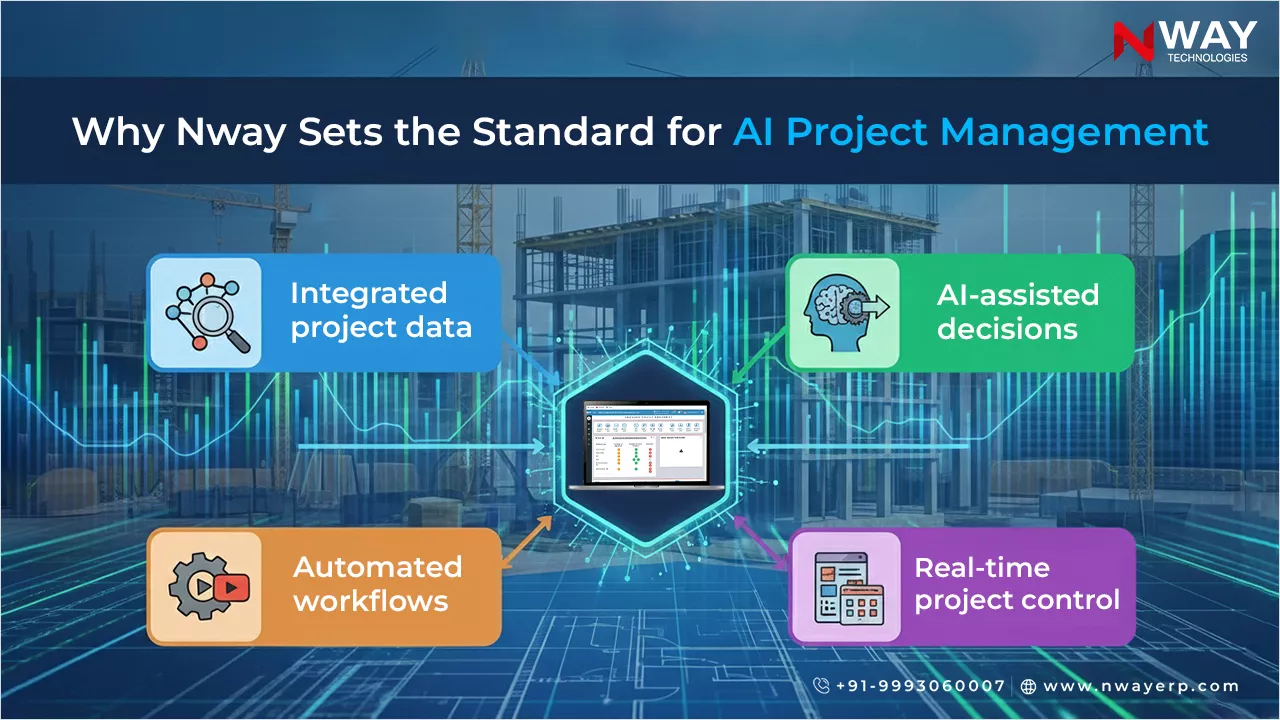

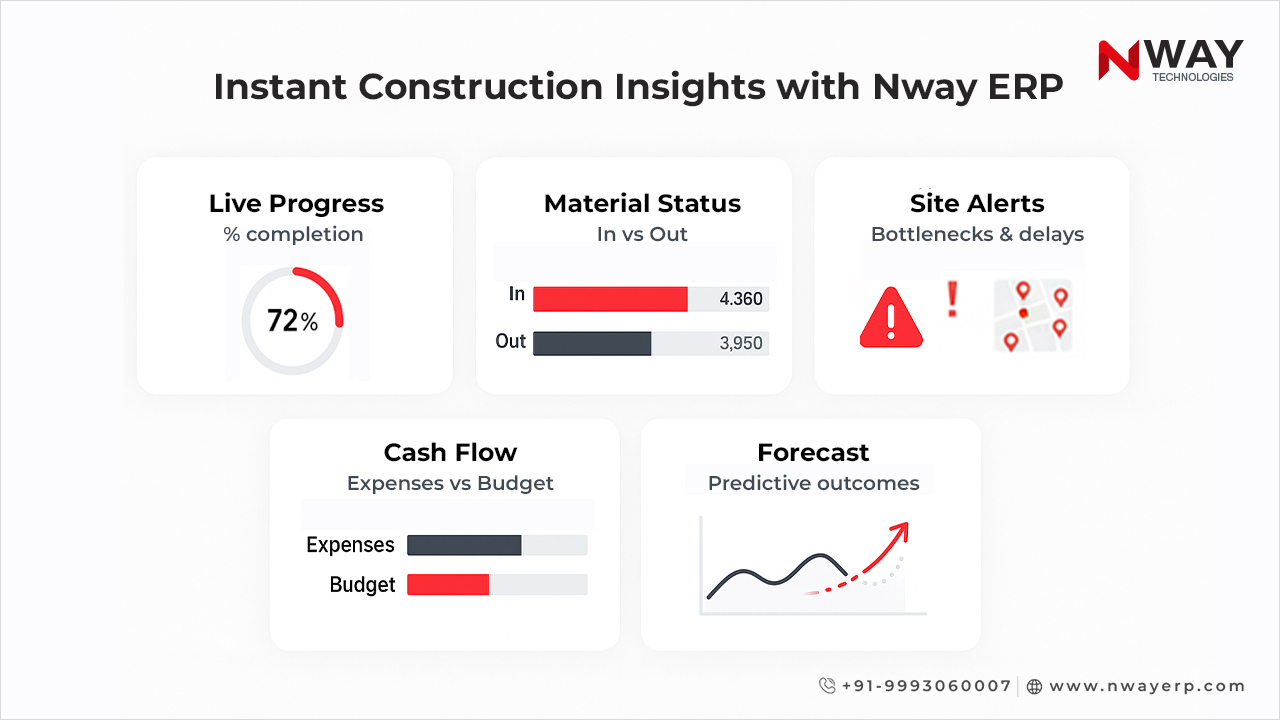

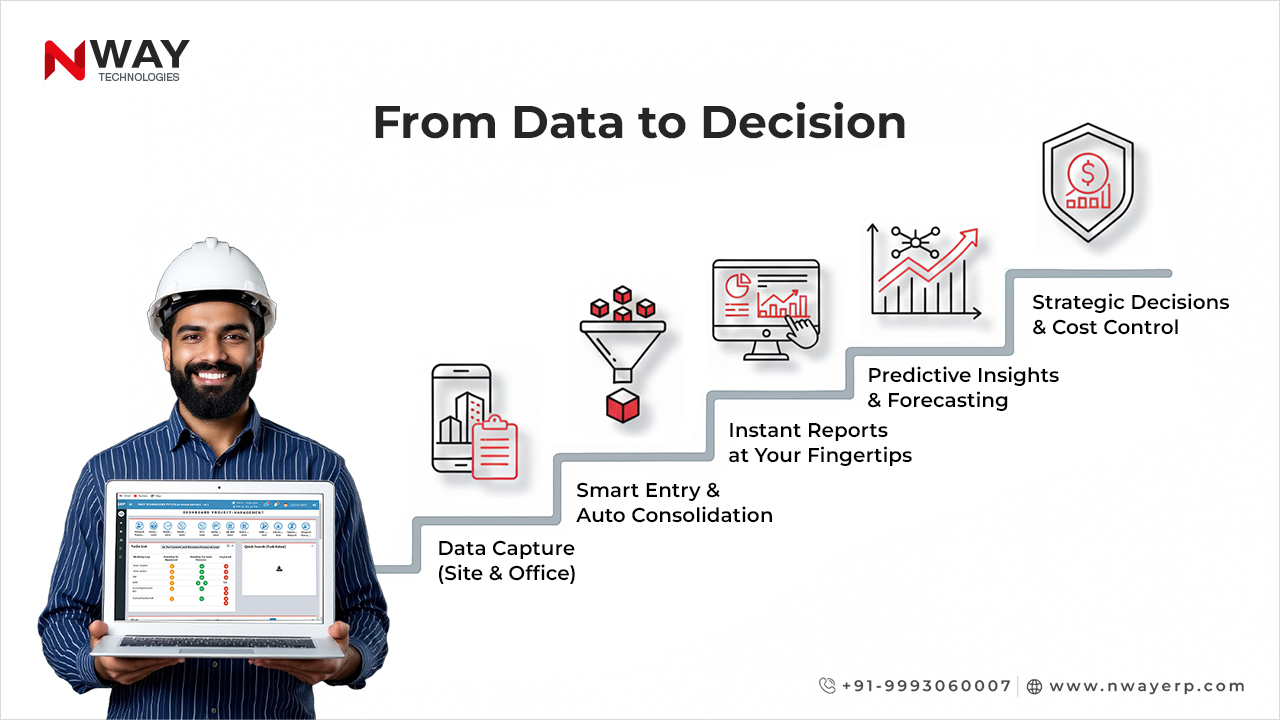

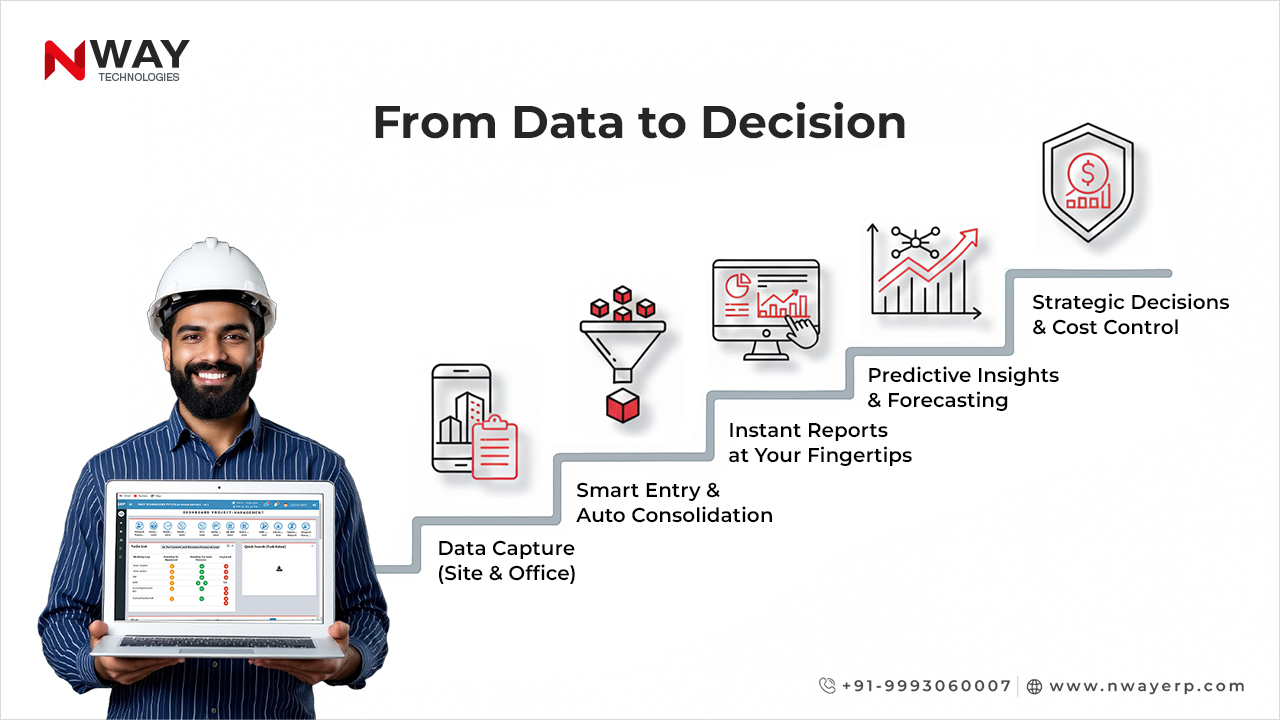

Predictive Insights, Real-Time Reports, and Cost Control

Construction projects face cost overruns, delays, data gaps, and material mismanagement. Nway ERP addresses these issues by combining AI intelligence with practical operational tools.

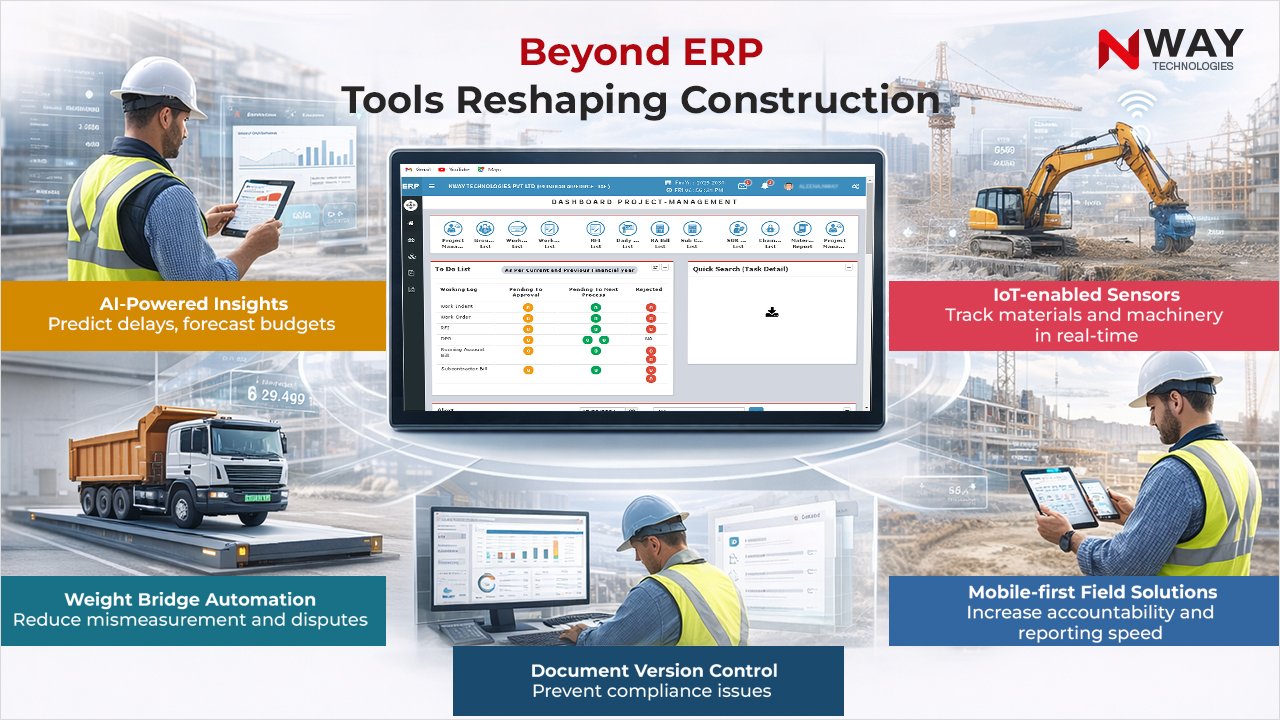

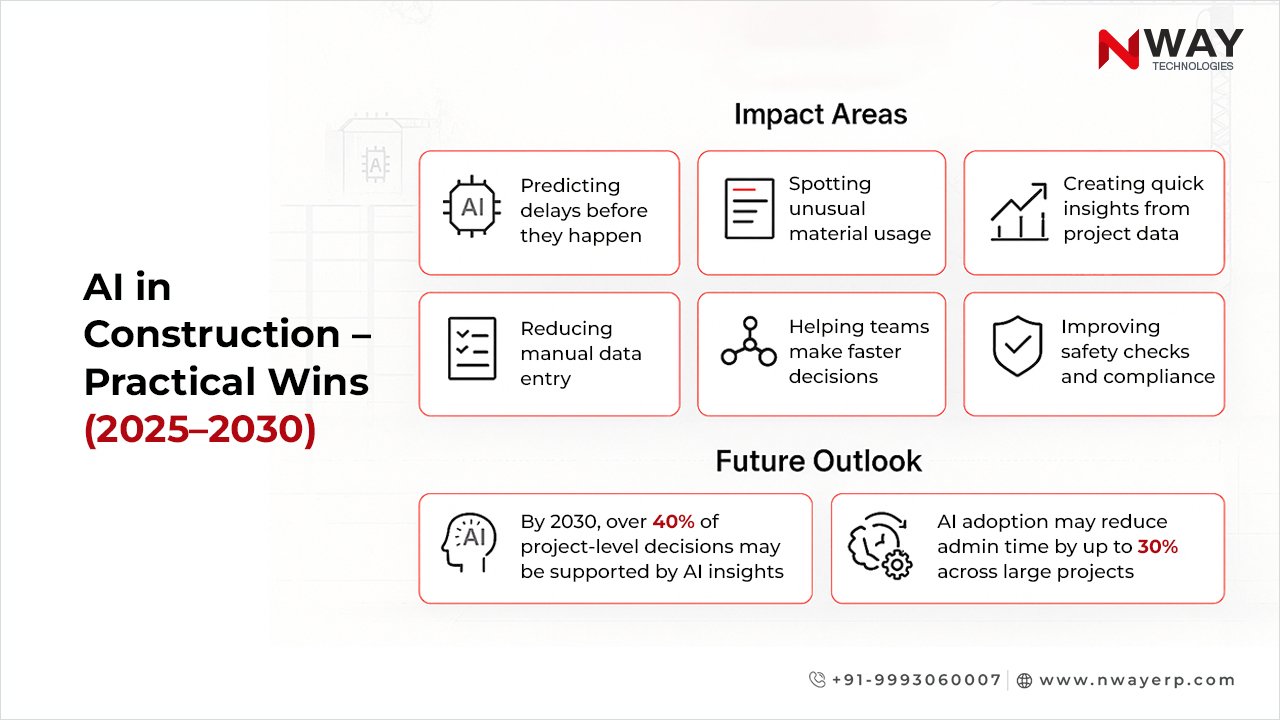

AI Assistant for Predictive Insights & Forecasting

Nway ERP’s AI Assistant continuously analyzes project data, including labor allocation, material usage, equipment logs, and past performance.

Impact: It predicts schedule conflicts, resource shortages, and cash flow risks. Project managers can reassign teams, adjust timelines, or pre-order materials before bottlenecks occur.

Smart Entry AI for Error-Free Data Capture

Nway ERP’s Smart Entry AI automates routine data inputs, from material receipts and weighbridge readings to labor hours and inventory updates.

Impact: Reduces human errors, ensures accurate project costing, prevents rework, and accelerates reporting cycles. Teams spend less time on data entry and more on strategic tasks.

Weighbridge Integration for Material Tracking

With Nway ERP’s AI features, weighbridge readings are directly captured into the ERP system in real time, linked to inventory and financial modules.

Impact: Accurate material measurement prevents overuse, ensures proper billing from suppliers, and maintains precise inventory levels. Managers can monitor material flow across sites without manual reconciliation.

Operational Benefits Across Features

- Faster, precise forecasting of costs, materials, and timelines

- Reduced rework, waste, and manual errors

- Clear visibility across multiple sites

- Improved cash flow, inventory management, and supplier accountability

Nway ERP turns fragmented construction operations into predictable, data-driven workflows, giving managers actionable insights while reducing manual overhead and operational risk.

Conclusion

Construction in 2026 is too complex for manual processes, fragmented systems, and reactive management. Rework, cost overruns, delays, and inefficiency remain costly and frequent – especially in large infrastructure, road, bridge, real-estate, mining, and multi-site projects.

AI enabled ERP software – combining automation, real-time data, predictive analytics, and integrated workflows – offers a strategic solution. It reduces errors, lowers waste, speeds approvals, improves forecasting, and consolidates control across the enterprise.

For firms serious about delivery, cost discipline, scalability, and profitability, adopting a construction-focused AI-driven ERP like Nway is no longer optional – it is essential.

If you are ready to move from fragmented operations to integrated control, request a demo of Nway ERP today. Evaluate how data-driven construction management can transform your projects and protect your margins.

Turn project data into actionable insights with Nway’s AI assistant.

Get real-time forecasts and instant reports to reduce delays and improve profitability.

FAQs

What is AI enabled ERP software, and how is it different from a standard construction ERP?

AI enabled ERP software combines the traditional features of construction ERP – like accounting, procurement, inventory, project tracking – with smart automation and data‑analysis capabilities. This means it can automatically process documents, forecast material and labor needs, detect potential delays or cost overruns, and deliver real‑time analytics. Standard ERP stores data and helps you organise it. AI enabled ERP helps you act on that data faster and more accurately. Construction firms using Nway ERP benefit from these AI-driven insights across multiple projects.

How can AI-powered ERP help reduce cost overruns and waste in road, bridge or infrastructure projects?

Construction on large infrastructure projects often involves heavy materials, frequent deliveries, and multiple sites. An AI-powered ERP can track materials (e.g., via weighbridge data), monitor inventory and usage patterns, forecast material demand and labor needs, and warn managers about likely shortages or overuse. This reduces over‑ordering, material wastage, unnecessary stock, and costly rework – which together commonly lead to project cost overruns. Nway ERP helps construction managers achieve these efficiencies with predictive analytics and automated material tracking.

Will implementing AI enabled ERP software improve project scheduling and on-site coordination for multi‑site projects?

Yes. Because AI ERP integrates data across departments and sites – procurement, materials, labour, equipment, financials – it gives a unified, real-time view. Managers get access to live dashboards showing status across sites. This enables smarter scheduling, better resource allocation, timely decisions, fewer delays, and smoother coordination even when multiple locations, subcontractors, and teams are involved. Nway ERP supports multi-site visibility to make these coordination improvements actionable.

Does AI ERP help in financial and regulatory compliance for construction firms?

AI‑enabled ERP helps track bills, invoices, receipts, payments, vendor records, material usage, and project costs in a structured and automated manner. This creates a clear audit trail, reduces manual errors, ensures transparency in bookkeeping, and simplifies compliance. It helps firms maintain accurate financial records and generate reports – reducing risk of compliance issues or audit failures. Construction firms using Nway ERP benefit from automated compliance tracking and error reduction.

What kind of return on investment (ROI) can a construction firm expect by switching to AI enabled ERP software?

While exact ROI depends on project size and operations scale, firms typically see savings through reduced rework, lower material wastage, fewer delays, improved cost control, faster approvals, and better cash flow. Over time – especially for multi-site or high-volume infrastructure firms – these savings add up. AI enabled ERP transforms unpredictable operations into predictable, efficient workflows, which improves profitability and reduces risk. Nway ERP enables these measurable ROI improvements with AI-driven insights and instant reporting.