Standard Operating Procedures (SOPs) help construction companies turn complex tasks into predictable, repeatable processes. In the construction industry, variability in execution, communication gaps, costly mistakes, and training delays are common. Using an SOP in construction industry creates a structured way of working that reduces guesswork and increases efficiency.

This blog explains how SOPs standardize project workflows, improve consistency, minimize errors, and improve efficiency. We also highlight how Nway ERP supports SOP‑driven process standardization and workflow automation in real project environments.

Table of Contents:

- What is an SOP in Construction Industry?

- Importance of SOPs in construction

- Benefits of SOPs in Construction

- Construction Business SOPs in Practice

- How Construction Process Standardization Drives Efficiency

- Real Challenges with SOPs

- Avoiding SOP Implementation Mistakes

- How Nway ERP Enables SOP‑Driven Efficiency

What is an SOP in Construction Industry?

An SOP in construction industry is a documented step-by-step guide for completing a task or process reliably. It tells workers how to do the job, who should do it, and when it should be done so that results remain consistent across teams and projects. Well‑written SOPs reduce miscommunication, speed up onboarding, and establish a clear framework for quality and safety.

Importance of SOPs in construction

Construction projects involve many teams – planners, site engineers, subcontractors, and finance staff. Without understanding the importance of SOPs in construction, teams may work in silos, create inconsistent outputs, or repeat mistakes. Standard procedures improve clarity and accountability for every task.

Research shows SOPs help companies cut defects and errors by 50–70% compared to undocumented workflows.

If your projects keep running over budget,

it’s not the team – it’s the process. Learn how Nway ERP standardizes workflows and keeps everything on track.

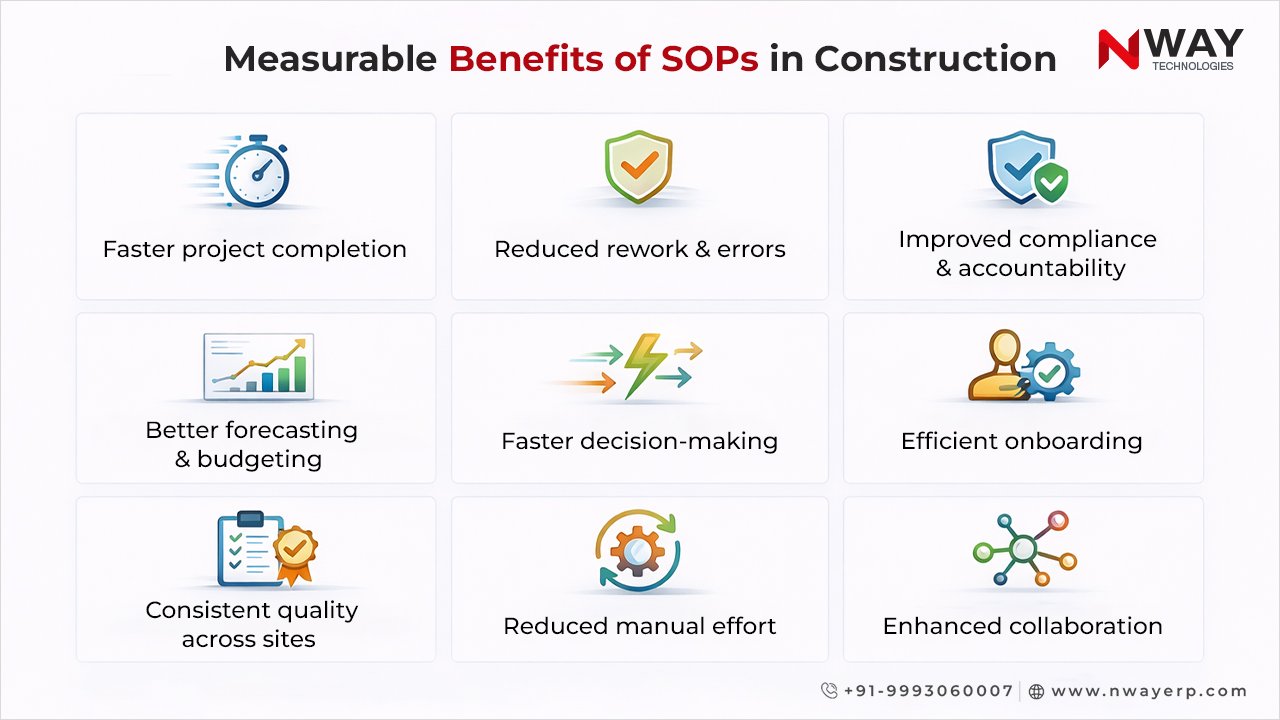

Benefits of SOPs in Construction

Standard procedures turn best practices into repeatable actions. Construction workflow SOPs improve efficiency by ensuring that every team member understands what to do and how to do it.

Some key benefits of SOPs in construction include:

Consistency: Uniform task execution across sites and teams.

Productivity: Workers spend less time figuring out how to proceed.

Quality control: Tasks are completed according to established standards.

Safety compliance: SOPs embed safety checkpoints that reduce risk.

Faster onboarding: New hires follow SOPs instead of repeating training cycles.

Industry sources note that SOP-driven workflows can reduce process delays by 40–50% in multi-site operations.

Construction Business SOPs in Practice

Construction business SOPs are applied to daily site workflows like material handling, inspection protocols, billing approvals, and procurement processes. For example, an SOP for material procurement might include when to place orders, how deliveries are inspected, and how stock updates are recorded. Clear rules cut down confusion and rework, making forecasting and budgeting more accurate.

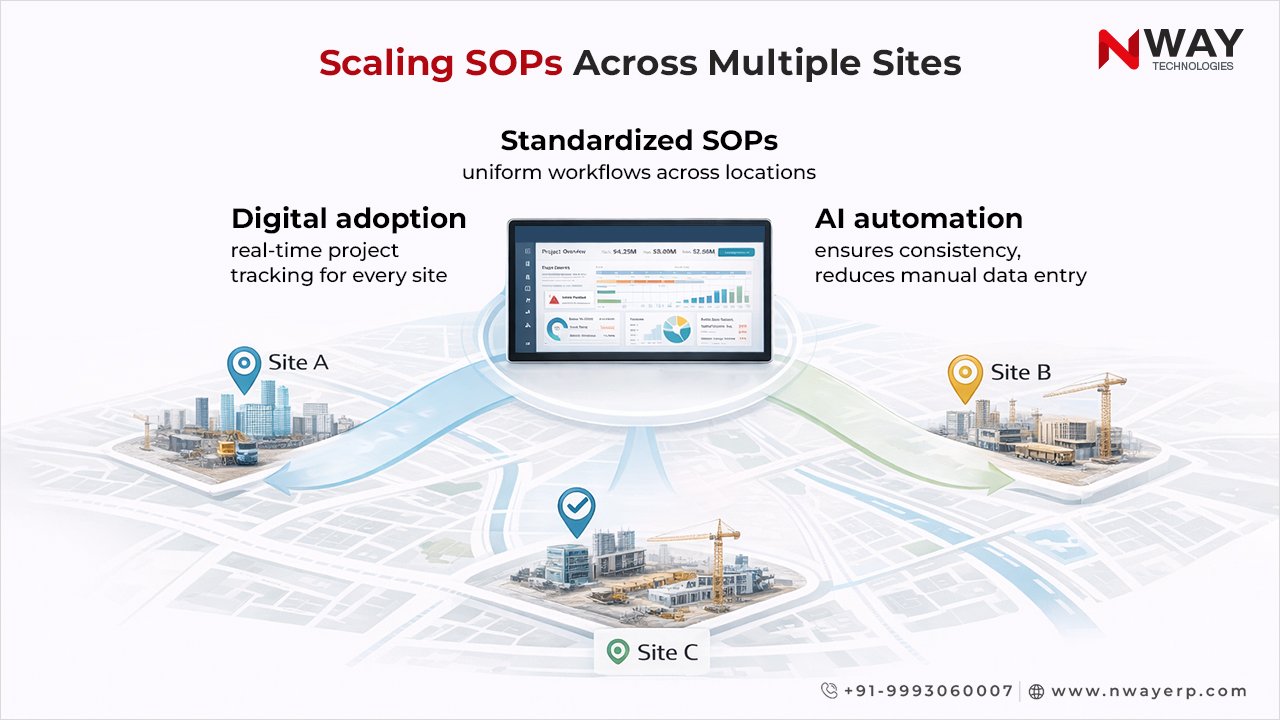

How Construction Process Standardization Drives Efficiency

When procedures are consistent and documented, teams waste less time on guesswork and ad-hoc decisions. Standardization lets managers track progress accurately, identify deviations early, and improve planning.

The global construction software market continues to grow as firms adopt tools to standardize workflows and analyze project data more effectively.

Real Challenges with SOPs

SOPs alone do not fix problems if they are merely documents stored in binders or folders. Many teams struggle because SOPs are:

- Difficult to access on the job site

- Not enforced or updated regularly

- Too detailed to use in real time

- Lacking integration with daily tools

In many construction companies, outdated or buried SOPs are rarely referenced, reducing their practical impact.

Avoiding SOP Implementation Mistakes

Well-written SOPs must be easy to access and enforce. Common pitfalls include:

- Storing SOPs offline where teams can’t use them

- Updating procedures irregularly

- Making SOPs overly complex

- Not tying procedures to tools daily used by teams

Using systems that enforce SOPs operationally – like Nway ERP – ensures teams follow processes and SOPs remain living tools, not static documents.

How Nway ERP Enables SOP‑Driven Efficiency

While SOPs define what should be done, Nway ERP ensures these procedures are executed consistently and measured for impact. By embedding SOPs into digital workflows, Nway ERP turns SOPs into action-ready processes that teams follow without extra effort.

Here’s how:

AI Assistant for Instant Insights

Instead of manual reporting, teams can ask Nway’s AI Assistant for instant reports, KPI snapshots, and forecast results using natural language. This eliminates report delays and supports faster decisions based on real project data.

SmartEntry AI for Invoice Entry

Finance SOPs often break down when bills and expenses are entered manually. SmartEntry AI automatically captures invoice data – purchase bills, GRNs, quotations, and general expenses – with high accuracy, reducing errors and cleaning up financial workflows in line with SOP rules.

Weight Bridge Automation

Sites that use manual weight capture waste hours entering vehicle numbers and weights. Nway’s Weight Bridge Automation records weights, identifies vehicles, and predicts item names. This automated step ensures material records follow SOP guidelines without manual intervention.

By tying digital steps to structured procedures, teams not only follow SOPs but achieve measurable efficiency: fewer manual errors, faster approvals, and consistent reporting across projects.

Conclusion

An SOP in construction industry is not just a document – it’s a foundation for clarity, quality, and efficiency. SOPs reduce errors, streamline workflows, support safety, and make training more effective. When paired with a digital system like Nway ERP that embeds procedures into daily work and leverages AI for reporting, automation, and compliance, SOPs turn from theoretical best practices into measurable operational improvements.

For construction businesses aiming to deliver projects on time and within budget while maintaining quality and control, standardization powered by SOPs and intelligent automation is essential.

Scaling to multiple sites?

Don’t let inconsistent processes slow you down. Nway ERP keeps all your teams on the same page.