In 2026, construction projects are moving faster, budgets are tighter, and clients expect updates in real-time. This is why DPR in construction, also known as the daily progress report in construction, has become more important than ever.

A well-made DPR helps site engineers, project managers, and business owners track daily work, avoid delays, and stay in control. It acts as a daily snapshot of your project, showing what was done, by whom, and what problems came up.

But here’s the problem – many companies still manage DPRs using paper or Excel. These outdated methods often lead to errors, delays, and miscommunication.

In this blog, we’ll explain what is DPR in construction, why it matters, the components of a daily progress report, and how to write one easily. We’ll also show how an ERP module for DPR can help you save time, reduce mistakes, and stay audit-ready.

Let’s dive in and understand the real benefits of DPR in construction, and how to make it work better for you.

Table of Contents:

- What is DPR in Construction?

- Why DPR Matters for Construction Teams

- Key Components of a Daily Progress Report

- How DPR Helps Beyond Just Reporting

- Why Manual DPRs are no longer effective for construction businesses in 2026

- Going Fully Digital: How ERP Supercharges Your Daily Progress Reporting

- How to Write a Daily Progress Report the Smart Way with ERP

- Why Nway ERP Leads the Way in Construction DPR Excellence

What is DPR in Construction?

DPR in construction stands for Daily Progress Report. It is a document prepared at the end of each working day on a construction site. It records all key activities completed during the day, resources used, and any issues faced. It gives project managers and senior management a clear view of daily site performance.

Many professionals search for “what is DPR in construction”, and the answer is simple: it’s a daily update on everything happening on site – people, machines, materials, and progress. It is one of the most important documents in construction project management.

The daily progress report in construction is usually created by the site engineer, project coordinator, or site supervisor. It is shared with the project manager, client, or headquarters. In large companies with ₹50 Cr+ turnover and multiple sites, DPRs help maintain transparency and control across all projects.

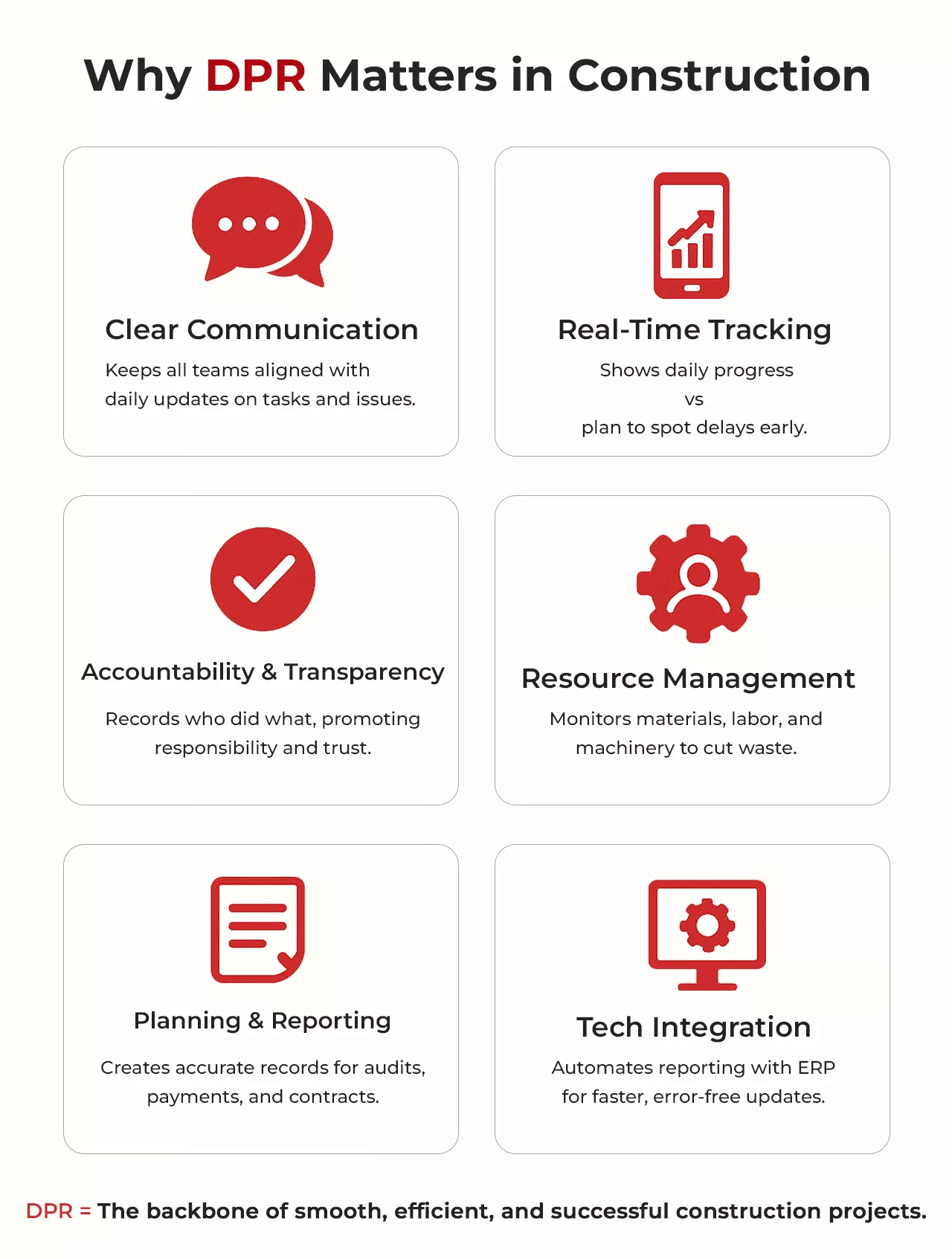

Why DPR Matters for Construction Teams

Understanding ‘why DPR in construction’ is essential helps teams improve project delivery and avoid costly mistakes. The daily progress report in construction is not just paperwork – it is a powerful communication and management tool that directly impacts how smoothly a project runs.

Clear Communication Across Teams

Construction projects involve many people- site engineers, laborers, vendors, contractors, and managers. Without a clear and timely daily progress report in construction, these teams operate in silos. A DPR ensures everyone knows what happened that day, what tasks are pending, and where problems lie. By recording key details every day, the DPR becomes a source of truth for the entire team. This clarity reduces confusion and prevents repeated questions or conflicting instructions.

Real-Time Progress Tracking

For construction companies handling multiple sites or large projects, keeping track of progress is challenging. A DPR offers a daily snapshot of completed work, helping project managers compare planned vs actual progress. This helps in identifying delays early. When the components of a daily progress report are detailed and accurate, teams can act quickly to fix issues before they cause bigger problems.

Accountability and Transparency

One of the main benefits of DPR in construction is building accountability. Since the DPR records who did what and when, it discourages shortcuts and promotes responsibility among workers and supervisors. It also creates transparency for clients and stakeholders who want regular updates on the project’s health. Transparent reporting builds trust and reduces disputes.

Effective Resource Management

The DPR tracks material consumption, labor hours, and machinery use. This helps project managers avoid wastage, shortages, or overuse – common pain points in construction. By knowing exactly how resources were used each day, teams can plan better for the following days, improving efficiency and reducing costs.

Basis for Future Planning and Reporting

Beyond day-to-day management, the DPR serves as a record for audits, payments, and legal compliance. It helps prepare weekly or monthly progress reports and supports contract management. For teams learning how to write a daily progress report in construction, focusing on accuracy and detail is critical to making the DPR a reliable reference.

Integration with Technology

Modern construction companies use software to streamline DPR management. An ERP module for DPR can automate data entry, enforce standard formats, and allow real-time updates from the site. This reduces human error and speeds up communication, making the DPR even more effective for teams. Thus, the DPR is the backbone of construction site communication, control, and accountability. It empowers teams to stay on track, avoid costly errors, and deliver quality work.

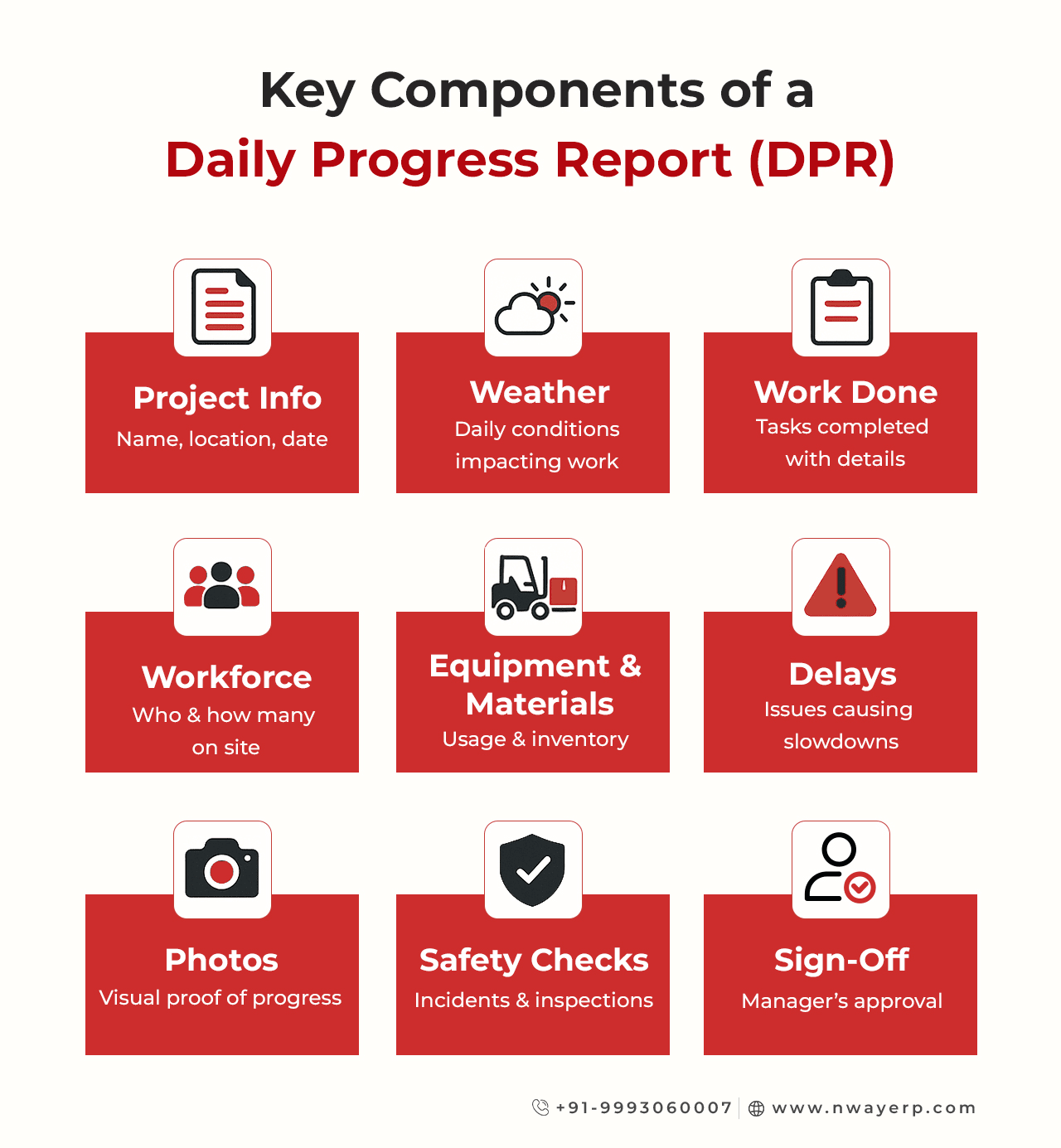

Key Components of a Daily Progress Report

To fully understand DPR in construction, it is essential to know its core parts. The daily progress report in construction is a detailed document, and each of its components plays a critical role in tracking the project’s health. Knowing these components of daily progress report helps construction professionals create accurate, useful records every day.

1. Project Details and Date

Every DPR begins with basic information: the project name, site location, date, and report number. This section helps in organizing reports and makes it easy to retrieve records when needed. Clear project details prevent confusion when multiple projects run simultaneously.

2. Weather Conditions

Weather has a direct impact on construction progress. Recording the day’s weather, such as rain, extreme heat, or wind, explains any delays or safety precautions taken. This is a vital part of the DPR because weather-related interruptions are common and can affect timelines.

3. Work Performed

This is the heart of the DPR. It details the specific tasks completed on that day. This section answers the question: What work got done? For example, it might include excavation details, concrete pouring, masonry work, or installation of electrical systems. The more precise and quantitative this section is, the better. Use measurements, quantities, and location references.

4. Workforce Information

Knowing who worked on-site and how many laborers were present is important for accountability and resource planning. This section lists the number of workers, types of skilled labor, and any subcontractors present. This helps monitor labor efficiency and costs. It also explains if low manpower caused slow progress.

5. Equipment and Material Usage

Recording which machinery was used and which materials were consumed helps track inventory and costs. For example, noting the number of cement bags used or hours of crane operation helps control wastage and plan for supplies. Tracking equipment also supports maintenance schedules and prevents breakdown delays.

6. Delays and Issues

Construction projects rarely run without problems. This section captures reasons for delays such as equipment failure, lack of materials, design changes, or safety incidents. Documenting these challenges in the DPR is crucial for transparency and helps management address issues quickly.

7. Photos and Visual Evidence

Including photos of the work site or completed tasks adds credibility and clarity to the report. Visual evidence supports written data and helps stakeholders verify progress remotely.

8. Safety and Compliance Checks

Safety is a top priority on construction sites. The DPR should record any safety incidents, inspections conducted, or compliance checks performed that day. This information is critical for risk management and maintaining workplace safety standards.

9. Signatures and Approvals

Finally, the report should be signed or approved by the site engineer or project manager responsible for accuracy. This confirms the report’s authenticity and readiness for further use in project tracking or audits.

What if you could save nearly 30% of admin hours every week?

Discover how Nway ERP makes it simple.

How DPR Helps Beyond Just Reporting

When you hear DPR in construction, you might think it’s just paperwork or routine updates. But a well-prepared daily progress report in construction is far more powerful. It’s a tool that helps site managers, project teams, and stakeholders make smart decisions every single day.

Imagine you are a site manager. Here’s how DPR transforms your work:

Spot Delays Early

Weather changes or unexpected site conditions can slow work. For example, if rain delays concrete pouring, the DPR highlights this immediately. You can adjust labor schedules or equipment use to avoid wasting money or causing cascading delays. Instead of discovering problems weeks later, you act right away.

Share Clarity with Stakeholders

Clients, consultants, and project owners want clear, honest updates. DPRs include photos and detailed notes that make progress visible and credible. When everyone sees the same facts, trust builds. This clarity reduces confusion and unnecessary follow-ups.

Avoid Billing Disputes

Payment delays and disagreements often happen when bills don’t match actual work done. The daily progress report in construction ties resource use and completed tasks directly to RA (Running Account) bills. This connection means less time spent resolving payment issues and more confidence in invoicing.

Identify Safety Gaps

Safety on site is non-negotiable. DPRs record observations such as missing helmets, blocked exits, or unsafe practices. These daily reminders help teams fix problems before accidents happen. Over time, this promotes a culture of safety awareness.

Gauge Resource Use Efficiently

Are workers or machines sitting idle? DPRs reveal when resources are underused or overstretched. This insight helps managers allocate manpower and equipment smartly, improving productivity and reducing costs.

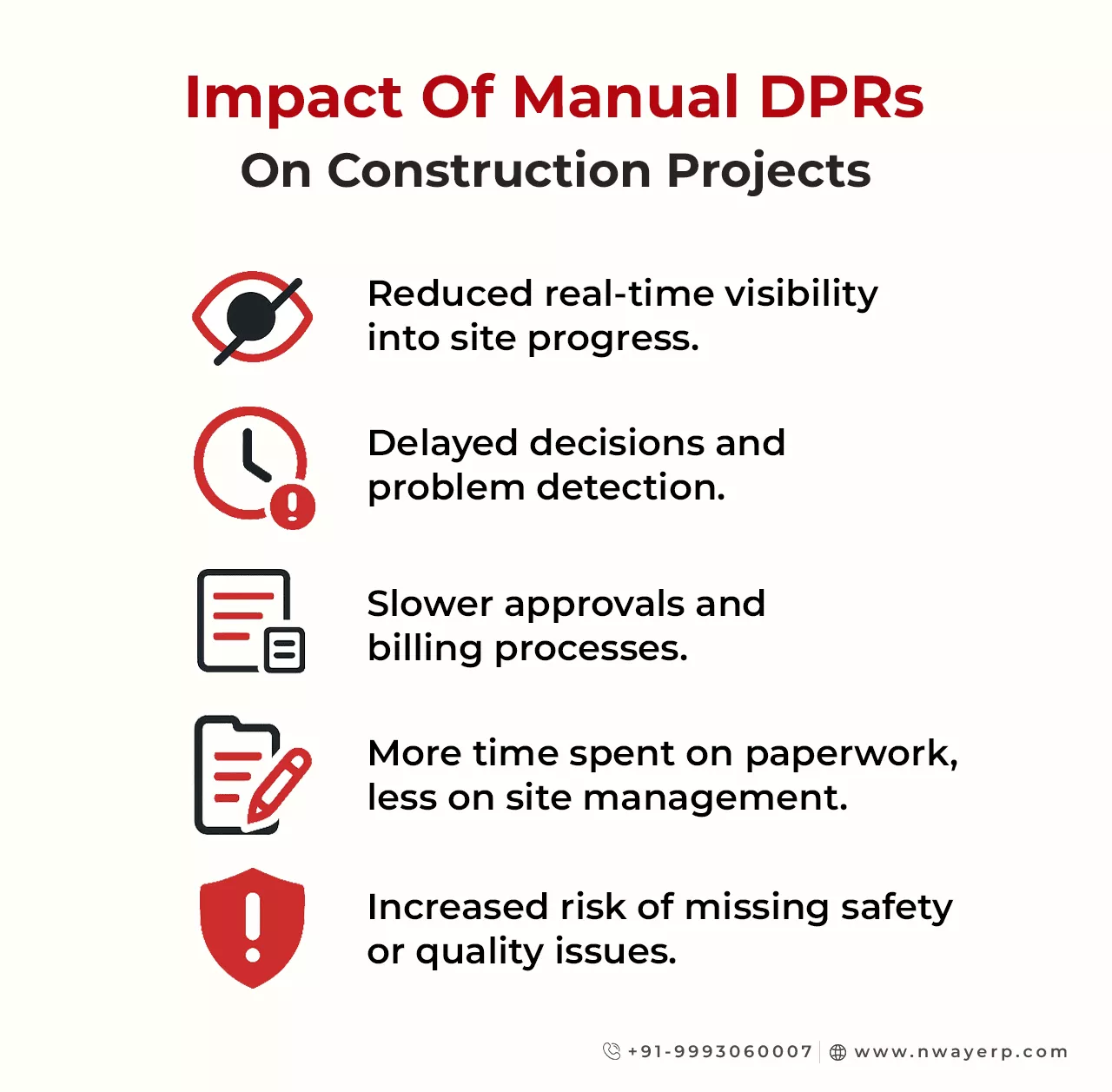

Why Manual DPRs are no longer effective for construction businesses in 2026

Managing a daily progress report in construction manually may work on small projects. But as projects grow, manual DPRs often become inefficient and prone to errors. Understanding why manual DPRs fail helps construction teams see the need for smarter solutions.

According to research from LetsBuild, project managers spend up to 40% of their day writing reports, chasing updates, and handling paperwork when DPRs are managed manually. This is time lost that could be used for managing resources, safety, and quality on site.

Here are the main reasons manual DPRs struggle:

1. Errors and Missing Information

Manual entry leads to typos, missed fields, and incomplete data. This lowers the reliability of reports and causes confusion during project reviews.

2. Reporting Delays

Manual DPRs are often filled out late or the next day, causing delays in sharing critical site updates. This slows approvals, billing, and problem-solving.

3. Inconsistent Formats Across Teams

Different teams or sites use various reporting formats, making it difficult to combine data or get a clear project overview.

4. Risks of Lost or Damaged Paperwork

Physical DPRs are vulnerable to loss or damage, risking important records and causing gaps in documentation.

5. Resistance to Standardized Reporting

Field staff may resist strict templates, leading to incomplete or inconsistent reports and missing vital information.

6. Difficulty Handling Complex Projects

As projects become larger or more complex, manual DPR management becomes inefficient and creates bottlenecks.

Going Fully Digital: How ERP Supercharges Your Daily Progress Reporting

Managing DPR in construction manually – on paper or Excel – is slow, error-prone, and tough to store securely. Digital DPRs revolutionize how daily progress gets tracked, shared, and acted on. Here’s how digitizing your DPR, especially via an ERP module for DPR, elevates everyday site management:

1. Faster Data Entry with Smart Tools

Digital DPRs offer dropdown menus, templates, and auto-fill features that make data entry a breeze. This reduces manual typing, speeds up entries, and ensures consistency across reports.

2. Instant Site-to-HQ Sync

Every update, from work done to materials used, syncs instantly to the dashboard. This real-time visibility helps project managers stay informed no matter where they are.

3. Built-in Approval Workflows

Role-based flows automatically route the report for sign-off—from site engineer to PM to finance. No chasing. No waiting. Just seamless approvals.

4. Error-Free and Complete

Digital systems include built-in validity checks and mandatory fields. That means no typos, no omissions, and fewer errors compared to manual entries.

5. Secure, Cloud-Based Storage

Say goodbye to lost or damaged paper. All DPRs are safely stored in the cloud, always backed up, and accessible whenever needed.

6. Insightful Dashboards and Analytics

Automated dashboards turn daily data into insights – highlighting productivity, delays, resource usage, and more, helping teams act proactively.

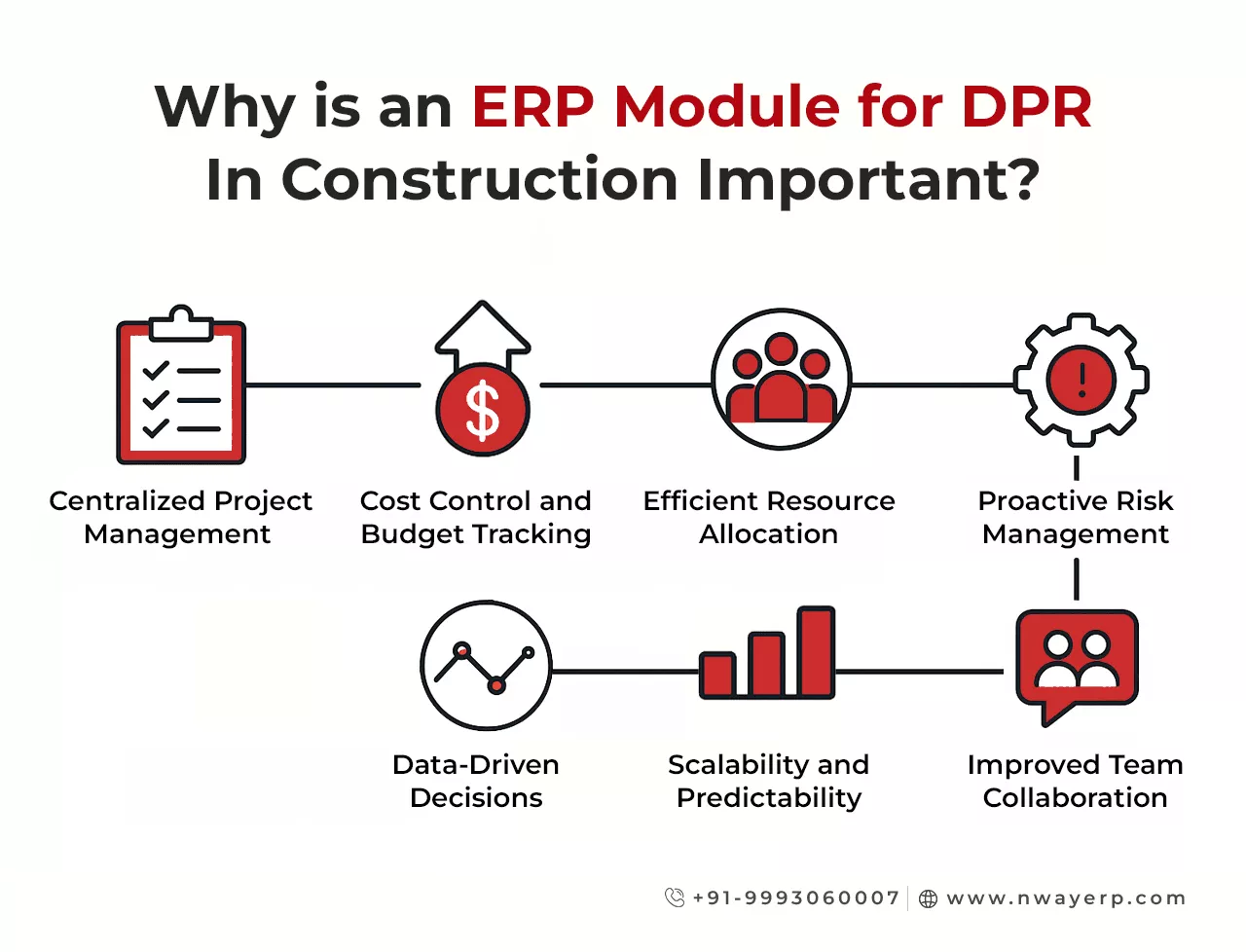

Broader ERP Benefits That Amplify DPR Value

ERP isn’t just for DPR – it elevates your entire construction process:

- Centralized Project Management: Plan, track, and adjust tasks, timelines, and assignments – all in one place.

- Cost Control and Budget Tracking: Compare estimates vs actual spend daily. Spot variances early and act fast.

- Efficient Resource Allocation: Track labor, material, and equipment usage to avoid shortages or idle time.

- Proactive Risk Management: Identify potential delays, shortages, or compliance issues before they escalate.

- Improved Team Collaboration: Everyone, from site crew to finance, sees the same live data, reducing communication gaps.

- Scalability and Predictability: As projects grow, ERP adapts – standardizing DPRs, templates, and workflows across sites.

- Data-Driven Decisions: Historical DPR data feeds predictive analytics, helping teams forecast bottlenecks and allocate resources wisely.

Improve resource utilization by 17% with live DPR insights.

Get Nway ERP today!

How to Write a Daily Progress Report the Smart Way with ERP

In modern construction management, writing a daily progress report doesn’t need to be slow or complex. With a well-designed ERP module for DPR, site teams can record work progress quickly, accurately, and in real time – without relying on outdated methods like handwritten notes or Excel files. Here’s how an ERP-based approach makes DPR in construction simpler, faster, and more reliable.

1. Use Pre-Built DPR Templates That Follow Industry Standards

A good ERP module for DPR comes with standard templates tailored for construction:

- Auto-filled fields for project name, date, weather, shift

- Structured sections for work completed, resources used, and site issues

- Space for uploading site photos or documents

Templates ensure consistency across all projects, reducing the chances of missing key data.

2. Capture Details on Site, in Real Time

Instead of end-of-day recollection, modern ERP apps let site engineers update DPRs directly from the site:

- Record tasks completed (e.g., “Shuttering completed for 2nd floor slab”)

- Upload images and geo-tag them

- Log observations like material delays or unsafe conditions

Real-time updates lead to better accuracy and faster decision-making.

3. Automate Labor and Machinery Logs

Well-built ERP systems offer dropdowns and auto-suggestions to log:

- Labor count by category (skilled, unskilled, subcontracted)

- Equipment usage hours, fuel, and idle times

This automation reduces manual data entry and ensures that key resource usage is tracked daily.

4. Track Materials Easily

ERP-supported DPRs prompt users to fill in:

- Material delivered (e.g., 200 bags of cement)

- Quantity used (e.g., 120 bags consumed)

- Opening and closing balance

With this, material stock levels stay accurate and procurement teams can plan proactively.

5. Log Issues Before They Escalate

A well-structured daily progress report in construction includes dedicated sections to report:

- Delays (weather, vendor, manpower shortage)

- Safety observations

- Coordination gaps between teams

This early visibility helps project managers act quickly before small issues become costly delays.

6. Route for Review in One Click

With ERP-enabled workflows:

- DPRs can be submitted with mandatory fields checked automatically

- Reports are routed to project managers or consultants digitally

- Status (submitted, pending review, approved) is visible to all stakeholders

This improves transparency and avoids back-and-forth emails or phone follow-ups.

7. Store Reports Securely in the Cloud

Unlike paper reports or offline files, ERP-based DPRs are:

- Automatically stored with backups

- Organized by project, date, or site location

- Accessible from anywhere – site, office, or mobile

There’s no risk of reports being lost, damaged, or corrupted.

8. Turn Daily Data Into Insights

An ERP designed for construction helps convert daily reports into useful dashboards:

- View daily vs. planned progress

- Track idle resources or productivity bottlenecks

- Flag repeated delays or material shortages

These insights help project managers and business heads make better decisions, faster.

Why Construction Teams Should Digitise DPRs Now

Still writing DPRs manually? Here’s why that’s a risk:

- Manual reports often lead to data gaps, typos, or submission delays

- Paper reports are hard to share and often lost

- Without digital data, you miss the chance to track trends or predict issues

Switching to an ERP module for DPR in Construction gives you real-time control, better accuracy, and complete visibility across all your sites.

Why Nway ERP Leads the Way in Construction DPR Excellence

When it comes to DPR in construction, having the right tool makes all the difference. Nway ERP stands out as a comprehensive solution tailored to the unique needs of the construction industry. Here’s why:

1. Integrated Daily Progress Reporting

Nway ERP offers a centralized platform where site engineers can input daily progress data, including work completed, materials used, labor deployed, and equipment status. This integration ensures that all stakeholders have real-time access to accurate information, facilitating timely decision-making and reducing the chances of errors.

2. Real-Time Data Synchronization

With Nway ERP, data entered on-site is instantly synchronized with the central system. This real-time synchronization ensures that project managers and other stakeholders have up-to-date information, enabling them to address issues promptly and keep the project on track.

3. Customizable Templates for Daily Reports

Understanding that each project may have unique requirements, Nway ERP provides customizable templates for daily progress reports. This flexibility allows construction teams to capture all necessary details specific to their projects, ensuring comprehensive documentation.

4. Mobile Accessibility

Nway ERP’s mobile capabilities empower site engineers to update daily progress reports directly from the field. This mobility ensures that data is captured promptly and accurately, even in remote locations, enhancing the overall efficiency of the reporting process.

5. Comprehensive Project Management Modules

Beyond daily reporting, Nway ERP encompasses various modules such as project planning, procurement management, inventory control, and financial management. This holistic approach ensures that all aspects of the construction project are seamlessly integrated, leading to better coordination and execution.

6. Enhanced Collaboration and Communication

The centralized nature of Nway ERP fosters improved collaboration among project teams, subcontractors, and clients. With shared access to real-time data, communication is streamlined, leading to fewer misunderstandings and more efficient project execution.

7. Robust Analytics and Reporting Tools

Nway ERP’s advanced analytics tools allow construction teams to generate detailed reports and insights from the daily progress data. These insights can be used to identify trends, forecast potential issues, and make informed decisions to keep the project on schedule and within budget.

By leveraging Nway ERP, construction teams can elevate their daily progress reporting processes, ensuring accuracy, efficiency, and enhanced project outcomes.

Choosing the right digital tools can transform how you write and use daily progress reports.

With smart solutions like Nway ERP, construction teams can take full advantage of the benefits of DPR in construction. This leads to smoother projects, happier clients, and stronger business growth.

Start making your daily progress reports work for you today – because every day counts on a construction site!

Construction teams using Nway ERP report 3x faster approvals with automated DPR flows.

Want that speed for your projects?