Construction projects rarely fail because of planning. They fail because teams cannot see what is happening in real time. Labor hours go unverified, materials are misallocated, and equipment appears available but sits idle. By the time errors surface, cost overruns and delays have already taken hold.

Construction management software addresses this gap. It captures real-time data, connects labor, materials, and equipment, and provides actionable insights. In India and the GCC, where projects span multiple sites and resources are complex, such visibility is critical for control and profitability.

Table of Contents:

- Why tracking breaks down on construction sites

- The role of construction management software

- Tracking labor with real-time data

- Tracking materials across projects

- Tracking equipment without manual logs

- When basic software falls short

- Why construction ERP software brings control

- What improves with one connected system

- How Nway ERP strengthens project execution

Why tracking breaks down on construction sites

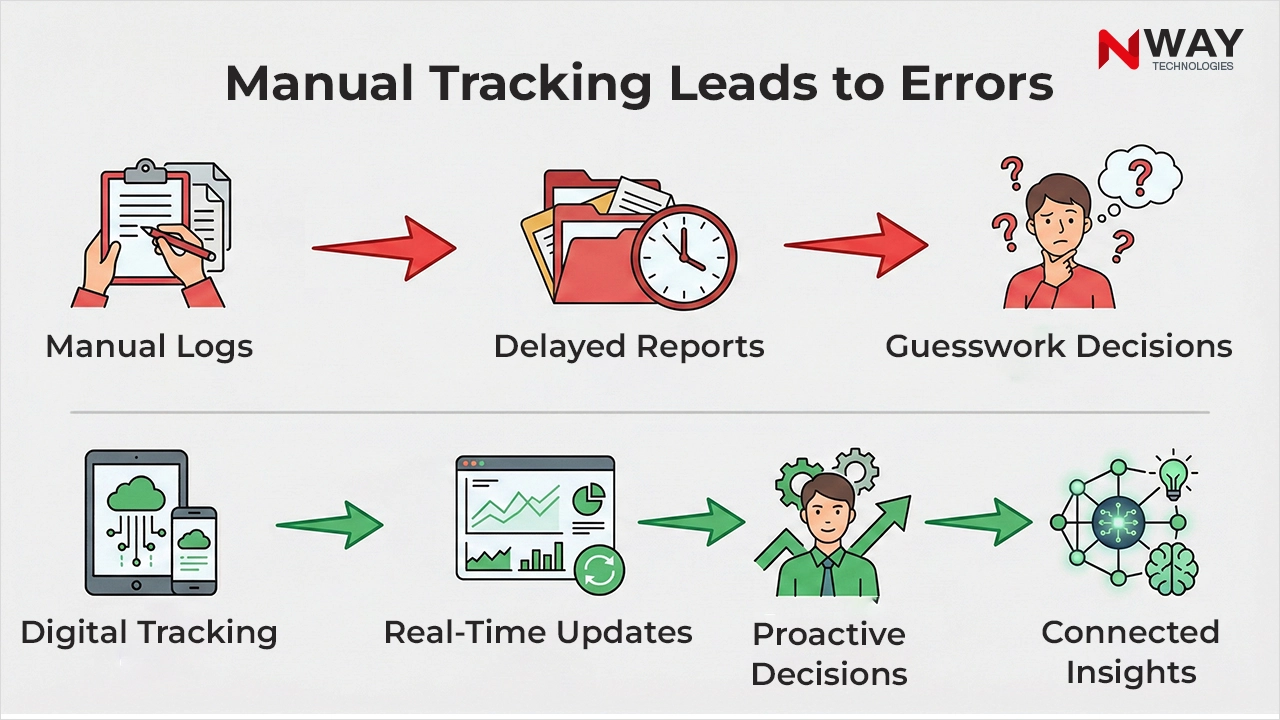

Many construction companies still rely on spreadsheets, manual logs, and delayed reports. Labor hours are estimated, material usage is reconciled late, and equipment tracking is inconsistent. These practices create blind spots that amplify risk.

In India, over 70 million construction workers make manual labor tracking unreliable across sites.

In the GCC, multi-site operations and leased equipment increase the cost of inaccurate tracking.

Key challenges include:

- Labor hours often reported weekly or monthly

- Material consumption tracked manually, prone to errors

- Equipment utilization poorly monitored

Without real-time visibility, decision-making is reactive and costly.

The role of construction management software

Construction management software consolidates operations into a single view. It captures data directly from site activities and delivers actionable insights in real time. Teams can monitor resource utilization, identify bottlenecks, and take corrective action before delays or overspending occur.

By reducing dependency on manual updates, the software turns visibility into operational control. Errors in labor allocation, material usage, and equipment deployment are caught before they impact project costs.

Tracking labor with real-time data

Labor is typically the largest variable cost in construction. Without timely tracking, inefficiencies go unnoticed. Construction labour management software monitors attendance, work hours, and activity completion, linking labor costs to projects and budgets.

Advanced systems provide predictive insights. Daily data on attendance and productivity identifies potential delays, allowing managers to reallocate resources proactively.

Benefits include:

- Early detection of productivity gaps

- Accurate labor cost allocation

- Reduced errors in payroll and reporting

Tracking materials across projects

Material costs often spiral due to over-ordering, delayed reconciliation, and mismanagement. Construction material tracking software monitors receipts, issues, and consumption, comparing actual usage to budgets.

Automated entry tools, like SmartEntry AI in Nway ERP, ensure purchase bills, GRNs, and quotations reflect real consumption. This helps teams prevent stockouts, minimize excess, and control procurement costs.

Material tracking impact includes:

- Reduced waste and cost overruns

- Faster procurement decisions

- Better alignment of material usage with project schedules

Tracking equipment without manual logs

Equipment is a major capital cost, yet underutilization is common. Construction equipment tracking software provides insight into hours used, location, and maintenance schedules.

With Nway ERP, automated integration captures equipment activity in real time. Predictive insights flag idle equipment and forecast maintenance needs, helping teams optimize deployment and reduce rentals or downtime.

Benefits include:

- Improved utilization of existing assets

- Reduced rental and maintenance costs

- Predictable operational planning

Prevent costly delays before they happen – get a clear view of every project.

When basic software falls short

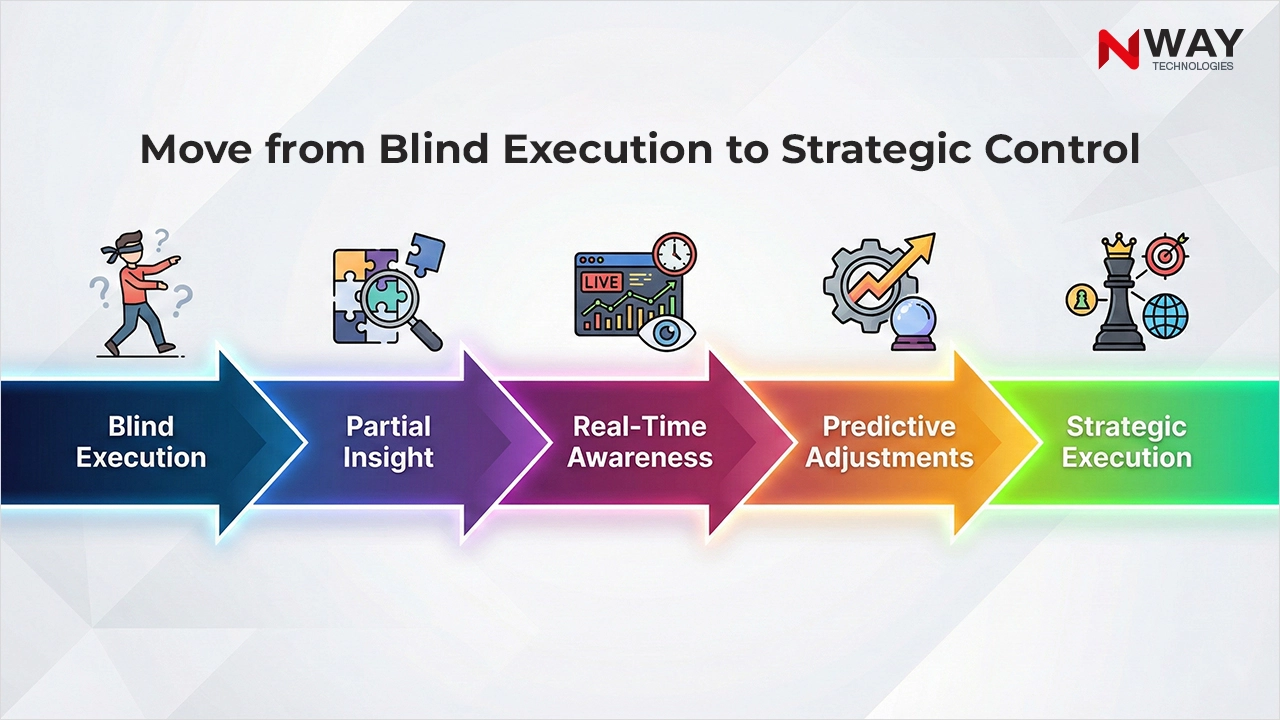

Standalone tools cannot unify labor, material, and equipment data. Manual reconciliation, delayed reporting, and disconnected spreadsheets continue to leave leadership blind to overruns. At scale, only construction ERP software ensures integrated control across operations and finances.

Why construction ERP software brings control

Construction ERP software connects operational insights with financial systems, creating a single source of truth. Labor, material, and equipment tracking feed directly into cost control, enabling informed decisions.

ERP adoption in India and GCC markets is growing steadily as firms recognize the need for real-time visibility and cost efficiency.

What improves with one connected system

A connected system transforms operations. Teams see cost trends immediately, forecast accurately, and eliminate manual reconciliation. Over 65% of mid-to-large construction firms are investing in integrated construction platforms for better visibility and profitability.

Key improvements include:

- Early detection of cost overruns

- Accurate forecasting and budgeting

- Streamlined reporting for management

How Nway ERP strengthens project execution

Nway ERP is designed to unify labor, material, and equipment management into a single, intelligent platform. Its modular architecture ensures that every aspect of construction operations is connected, from daily workforce deployment to material consumption and equipment utilization.

Our key modules include:

- Labor Management: Tracks attendance, task completion, and productivity across multiple sites. AI-driven insights alert managers to potential shortfalls before they impact schedules.

- Material Management: Automates entry of purchase bills, GRNs, and quotations using SmartEntry AI, ensuring data accuracy and preventing waste.

- Equipment Management: Integrates weight bridge automation and predictive usage tracking, highlighting idle machinery, maintenance needs, and optimal deployment.

- Project Monitoring: Central dashboards consolidate labor, material, and equipment data with budgets and timelines, providing a single source of truth.

Nway ERP’s AI capabilities are subtle but powerful:

- AI Assistant: Generates instant reports, KPIs, and predictive forecasts from natural language queries.

- SmartEntry AI: Eliminates errors in invoice and material entry, improving procurement accuracy.

- Weight Bridge Automation: Captures vehicle weights, item identification, and usage patterns automatically.

Operational impact is immediate:

- Labor efficiency improves as managers reallocate resources proactively.

- Material costs drop due to accurate, automated tracking.

- Equipment utilization rises while maintenance downtime decreases.

- Real-time dashboards allow proactive decision-making across multiple sites.

By combining modular design, AI-powered automation, and actionable dashboards, Nway ERP transforms construction operations from reactive management to proactive control, turning operational data into measurable business outcomes.

Conclusion

Construction projects in India and the GCC operate at scale, with complex labor, material, and equipment management needs. Construction management software is essential for real-time tracking. When extended into a platform like Nway ERP, operational visibility becomes actionable control. Companies reduce waste, prevent cost overruns, and make decisions with confidence. Nway delivers clarity, foresight, and efficiency, enabling projects to execute on schedule and within budget without adding administrative burden.

Stop guessing, see exactly where your labor, material, and equipment are right now – only with Nway ERP.